Whitepaper: Printed electronics technology opens new opportunities

Learn about printed electronics technology and find out why this exciting and emerging technology will become ubiquitous in the future.

What is printed electronics technology? What are its unique characteristics and advantages over silicon-based electronics? How can we benefit from printed electronics when designing electronics systems and products? In what kind of applications can this technology be used?

Find the answer to these and many more questions in our whitepaper ‘Printed electronics and their applications’ (see download on this page). Here is a preview of the whitepaper:

A new era for electronics

For more than 60 years, electronics have been manufactured on silicon or other semiconductor materials. The procedure includes complex processing in a time-consuming sequence of multiple steps. Nonetheless remarkable miniaturization, high-performance and low power is achieved. On the other hand, creating flexible and stretchable silicon-based electronics is more challenging.

To address these challenges, a new technology has emerged, the printed electronics. The whitepaper gives insights on this technology, focusing on how it can be used in practical applications.

What is printed electronics about?

The printed electronics technology is a novel way to manufacture electronics, using standard graphic arts printing processes, such as screen printing, flexography and inkjet printing, various types of electronic devices and circuits can be fabricated on unconventional substrates. Almost any material can be used for this purpose - plastic, textiles and paper are some good examples of such surfaces.

Such next-generation electronics can inherently take unique form factors and they can be ultra-thin, flexible and stretchable. Moreover, printed electronics use a simple and cost-effective low-temperature manufacturing process and are compatible with fully automated mass production printing by the roll-to-roll principle.

Creating hybrid electronics systems

It is unlikely that printed electronics will be able to compete with conventional silicon-based electronics when it comes to performance, reliability and ability to handle complex designs. But the possibility of embedding electronics in any object and shape and at a low cost is very attractive. Therefore, the printed electronics should be regarded as a complementary technology to the conventional electronics.

This realization inspires the creation of hybrid electronics systems. These can exploit the best of the two worlds and mitigate their limitations. Such a hybrid system typically comprises a single or multiple silicon integrated circuits (ICs) for computational power and wireless communications, and sensors, actuators and perhaps display manufactured with the printed electronics technology. The system can either be integrated on a flexible substrate as a whole or split in a rigid and flexible part.

How about applications?

Thanks to all the unique characteristics of the technology, printed electronics open up new possibilities for many fascinating applications that are either not feasible with or not an ideal fit for the silicon-based electronics. Printed sensors constitute the most prominent share of the printed electronics market and various sensor types can be manufactured in all sizes and shapes on thin foils. Humidity, strain, force and gas sensors are some examples of those.

Useful for IoT

Internet-of-Things (IoT) products in retail, healthcare, wearables, industrial and consumer applications are exceptionally benefitted by using printed sensors.

One practical example is a fall detection system, which consists of sensors that are embedded under the floor in housing units for elderly people and assisted living facilities. This system can monitor people’s position and movements in a room and detect cases when the care assistants’ help is urgently required.

In another example, a matrix of several force sensing elements printed on a flexible and thin plastic foil can be integrated to warehouse or retail shop shelves. These sensors can be used to build a monitoring system that can send alerts when the stock levels go below a threshold.

Read the full whitepaper

Download our whitepaper ‘Printed Electronics and their applications’ to find out more about this exciting and emerging technology that will become ubiquitous in the future.

Related content

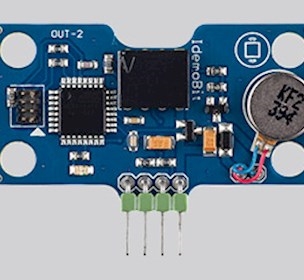

IdemoLab

/Facility

Bridging the gaps between new hardware technologies, design thinking and business development.

Make better dairy production decisions

/Article

Digital twins and Augmented Reality help improve Clean-In- Place planning at Arla Foods facility.

White paper: Product Service Systems

/Article

Interested in getting a general understanding of Product Service Systems in production companies?