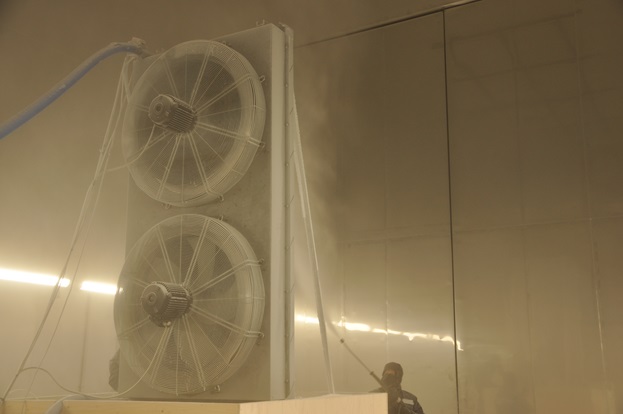

Stress test of the cooling system in FORCE Technology's climate chamber

Both the climate chamber and the cooling system in FORCE Technology's climate testing facility passed the stress test brilliantly.

FORCE Technology required a series of tests of the climate chamber from the German supplier, Engie during which the outer technical boundaries were challenged to their maximum.

Thermal stress testing - in real life conditions

FORCE Technology’s purpose with the test was to try the climate chamber’s yielding capacity during load, including low temperatures and moist at the same time.

Nissens A/S’ primary purpose was to perform a thermal stress test of the entire cooling system and validate the integrity of the individual components (e.g. cooling surface, pumps, valves and cooling pipe assemblies), while the system was in operation, under the same conditions as in a real operating context.

During the test, the climate chamber’s temperature counterbalanced an extreme outdoor temperature of - 30 °C with a simultaneous wind speed of 5-10 m/s. Nissens A/S’ cooling system was operated with temperatures from -20 to approximately +50 °C. In total, 400 cycles were performed over 7 days.

Icing

As a conclusion to the test, an icing test was performed, during which the entire cooling surface was sprayed with water that froze on the cooling surface. The purpose of the test was to prove that a static iced cooling system performs correctly when started in cold condition. After complete freezing, the cooling system was started up with warm fluid.Nissens A/S says:

”Contrary to previous tests, the facilities with FORCE Technology, made it possible to test the entire cooling system, when it had previously only been possible to test individual components. The facilities provide a more realistic simulation of thermal stress, the cold start of the pump station and icing of cooler and fan engine than we are usually able to perform ourselves”.

Both cooling system and climate chamber passed the test

Thus, the conclusion from Nissen is that is has been an extremely rewarding test, which is a very short time has made it possible to conclude the individual components’ strengths and weaknesses and provided very important inputs to monitoring the cooling system.

Søren Granskov, Sales Manager for the test centre says: ”With this commissioning test we have proven that the overall purpose of building the test facility has been reached. We predict that the huge flexibility of the climate chamber will provide many companies with significant advantages when it comes to performance and integrity testing entire systems, before mounting them in e.g. offshore sites.”

If you need any further material or if you and your colleagues should wish to see and discuss the possibilities of climate tests, you are very welcome to contact us.