Establish or redesign a well-operating port turning basin

A well-operating turning basin is of vital importance for the port efficiency. But when establishing or re-designing a turning basin does it make sense to follow existing guidelines?

There are many parameters to take into consideration when designing a turning basin, e.g. the depth and dimension of the turning basin, tug size and number to be used. In this article we will address how and why it is important to challenge the existing guidelines regarding depth and diameter of the turning basin.

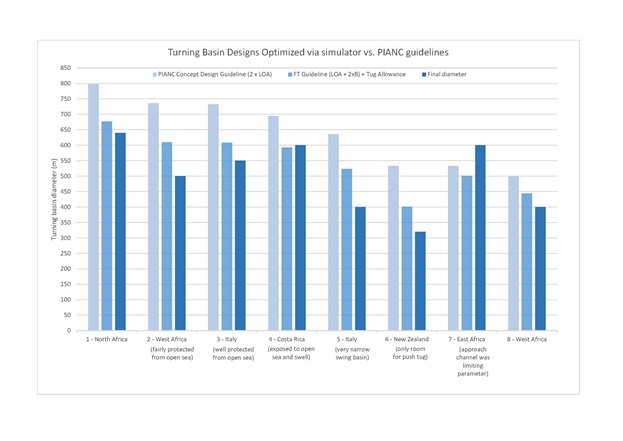

The PIANC guideline provides safe but also generally quite conservative dimensions for the basic design, thereby initially catering more for the manoeuvring conditions and less for the cost of dredging and maintenance.

In practice safe manoeuvring conditions can be achieved with turning basins with considerably smaller dimensions. By using the simulator and our long experience we have developed a rule of thumb when dimensioning a turning basin.

Optimising by rule of thumb

Over the years, our experience has shown that a good, yet also still conservative, empirical estimate is that the minimum diameter should equal the vessels length plus twice the breadth.In addition to this, there must be room for the tug boats to operate. As a rule of thumb, the diameter should be increased with two times the towline length (minimum 40 m) plus the length of the tugboat. This simple approach advances the basic design phase considerably as the estimated size is closer to the optimal size.

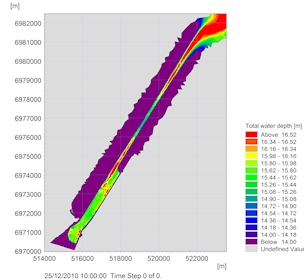

Obviously, the water depth at the perimeter of the turning area, where the tugboats operate does not necessarily have the same depth as the actual basin. However, port authorities often choose to dredge to same depth in the entire turning area’ says Jens Bay, Senior Project Manager.

The recommended diameters by PIANC and FORCE Technology are compared with the final and actual diameter in the figure above. As illustrated there is a considerable time and cost saving potential in addressing the most accurate diameter of the basin from the start of the project as even small reductions have a huge impact on the volume of material to be dredged.

Always remember to involve the stakeholders

‘Our way to optimise the size is really to perform a series of simulations embracing the prevailing environmental and operational conditions. The use of smaller basins requires more attention when entering the basin. The challenge is really to enter at the right position and with the right heading thereby accounting for the actual conditions and tug boat availability.

That’s why we recommend that the local pilots get involved in the design validation phase so that all stakeholders are accounted for’ says captain Jens Tommerup and continues ‘just recently we did a session with a turning basin in the middle of a long access channel. The simulations quickly showed that using the PIANC guidelines would provide an unwarranted large basin.

In the end a basin slightly larger than what our own rule of thumb indicated was opted for as this would enable larger vessels in the future to call at the port, but in the end, we were still able to reduce the diameter with 35 m and thereby save the port considerable dredging and maintenance costs. A result which was verified by the local pilots who supported the final dimension, and also a result which proves that doing a parametric study where manoeuvrability and operability are weighed against cost may be a very healthy investment’.

‘A design is always some sort of a compromise, but we believe we have developed a pragmatic and proven method which takes manoeuvrability and operability into account and at the same time balancing the construction and future maintenance costs’ says Jens Bay.