Visualising wind loads

Wind loading is an important design parameter for all building structures. For some structures, the wind loading even constitutes the most important load scenario to be considered in the design.

Wind loads according to codes

When designing a building, codes of practice, e.g. Eurocode, can be used to identify the local and global peak wind loads for simple geometries. However, such codes include neither larger or complex buildings nor irregular architectural constructions. Thus, it falls upon the designers to determine the wind loads, both local – cladding loads – and global loads. In these cases, wind tunnel testing is a recognised approach.

A wind tunnel test can reveal the characteristic wind load for any geometry. Sometimes, it is found that the design of the building must be changed, because the building would otherwise be subjected to excessive suction, extreme wind pressure or high wind-induced vibration. This way wind tunnel tests provide data and information to solve problems the customer would not be able to solve or even discover by using codes of practice.

Experimental assessment of wind loads

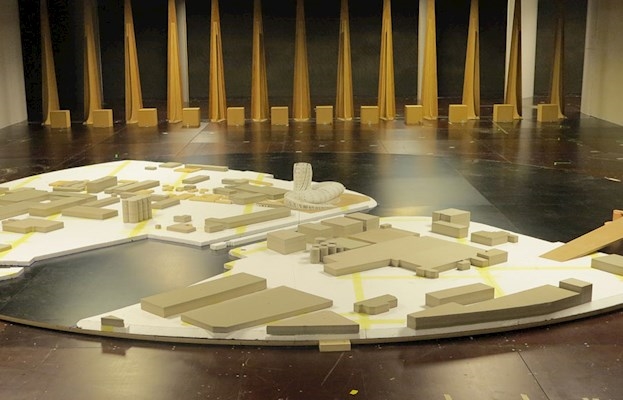

Surface pressures and cladding loads can be determined for even the most unusual structures by using a High-Frequency Differential Pressure Measurements System (or DPMS). Wind tunnel testing of scaled models under simulated site-specific climatological conditions can accurately provide both static and dynamic wind pressure loads and coefficients that can be used directly for structural design of both cladding loads, floor-by-floor loads and global loads.

With a dynamic pressure measurement system, it is possible to visualise the results real-time while the model is being tested in the wind tunnel. The benefit of the real-time visualisations is a stronger understanding of wind loads during the tests as the engineer and the customer are able to see the same thing.

With the opportunity to determine the actual wind load on the building regardless of the geometry, it is possible to optimise the construction with respect to wind loads. Even the narrowest corner of a building can be addressed.

The gift of visualisation

Normally wind is invisible, but the system’s visualisation tool allows us to see the contour plots of the wind pressure on the building. This allows performing part of the optimisation in real-time, whereas previously each configuration required manual post processing. This visualisation tool enables a better understanding of the wind loading process.

The DPMS system is a multi-channel system that can measure both mean and time-varying pressures on up to 1024 channels. The system has a frequency response of several kHz for large channel counts, making it ideal for measuring fluctuating pressure distributions.

Case