Simulator based ship-to-ship transfer training

FORCE Technology has designed and carried out a range of simulator-based courses focusing on ship-to-ship (StS) training for marine pilots, mooring masters, tanker captains and tug masters involved in these operations.

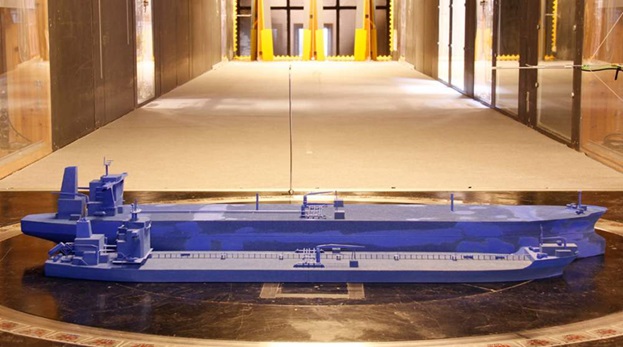

Mooring ships side by side in open waters involves significant risks, including pollution, fire, and explosion. FORCE Technology is able to determine the load on moorings between ships in ship-to-ship operations in our wind tunnels. This knowledge will help prevent hazardous situations, as will having well-trained officers in charge of the operations.

StS training in the full-mission simulator

Part of the benefit of carrying out extensive full-scale simulations involving tug, mooring masters, loading masters, pilots and tanker captains is that it prepares them for carrying out the operations in real life. During the simulator training teamwork, procedures and checklists will evolve and match the real job by assessing the safety level and reduce costs by increasing the efficiency of the operation.

The whole operation is carried out with up to 4 interactive tug simulators navigated by tug masters assisting the vessels during the manoeuvers.

Based on results derived from our towing tank and wind tunnel tests, the realistic environmental forces and effects on the implicated vessels are simulated, including forces on mooring gear and fenders.

Load coefficients in the wind tunnel

For the individual ships, load coefficients are often available, either as determined in wind tunnel tests, CFD calculated or from data-bases. However, since the ships are in close proximity to each other, using data for single ships may result in incorrect mooring forces.

In a side-by-side configuration or if the ships are moored together, the nearby ship will influence the flow conditions and, hence, the loadings on the moorings.

The wind tunnel expertise

FORCE Technology has been involved in determination of wind and current load coefficients for offshore vessels, e.g. FPSOs and FLNGs, for more than 40 years.

Test setup and load coefficient methods

For the past 10 years we have been involved in several side-by-side mooring studies, and as a result of the increasing demand for establishing wind and current load coefficients in shielded environments, FORCE Technology has developed in-house procedures for carrying out such wind tunnel tests. The wind and current load coefficients are obtained for a single body configuration as well as for a combined body (side-by-side configuration). We design test configurations in close collaboration with customers, ensuring they meet their specific needs. The tests are performed in one of our five wind tunnels.

Wind loads are determined in a boundary layer wind profile that resembles the ocean wind with respect to velocity distribution and turbulence intensity. The current loads are determined in a uniform wind profile with low turbulence that resembles the vertical current profile.

Non-dimensional force and moment coefficients are presented in both tables and graphs for easy use, allowing full-scale forces and moments to be directly calculated or used as input in the mathematical models used by the FORCE Technology simulators.

Benefits of a wind tunnel mooring study

Wind tunnel tests enable accurate determination of wind and current load coefficients for the particular design of the vessels and their operational configuration. This is a key parameter for safe and efficient design and operation.