Truck innovation required certification for market entry

Certification in the auto industry is complex. Oakhill Technologies needed expert support to get their wireless truckload monitoring system certified quickly, ensuring compliance and market entry.

Challenge

As a new entrepreneur, navigating certification rules required precision to ensure compliance and market approval.

Solution

Through expert guidance, structured testing and real-time adjustments, the certification process ensured compliance and market approval.

Result

The Oakhill Weight System is fully certified, market-ready and adopted by a major Northern European truck manufacturer.

Precision matters: The challenge of truckload management

For truck drivers, precise load weight control is critical. Overloading risks hefty fines or even an immediate license suspension, while underloading leads to wasted capacity and lost earnings. Yet, most weighing processes require drivers to exit the cab, move back and forth, and rely on rough estimates—all under tight deadlines.

After years behind the wheel, Patrik Lundell saw these challenges firsthand. He watched fellow drivers struggle to adjust loads manually, often second-guessing weight distribution. Determined to find a better solution, he started thinking about a wireless weight monitoring system that could provide real-time, accurate load data at the driver's fingertips.

From an idea to a game-changing tool for smarter truck-loading

What started as a simple idea quickly turned into a relentless pursuit of a better solution. Early product prototypes had their challenges, like limited range and inconsistent performance, but Patrik Lundell refused to give up. He taught himself electronics, designed custom circuit boards and ran countless tests, refining the system until it was reliable, accurate and ready for the road.

Bringing the Oakhill Weight System to market, however, required more than just technical breakthroughs—it demanded certification to meet strict industry standards.

"For new entrepreneurs like me, certification can feel like an obstacle course—complex, time-consuming, and filled with potential pitfalls. Missing a single requirement can lead to costly delays," Patrik says

Certification done wrong delays market entry and drives up costs

When it came time to certify the Oakhill Weight System, Patrik initially worked with a small local firm, which he discovered had critical flaws in its knowledge and certification process. Realising he needed a partner who could navigate the process with speed, precision, and hands-on support, he turned to us after finding out we'd worked on the brobizz, a wireless toll payment system used on Scandinavian roads, bridges and ferries.

Expert guidance secured fast certification for the Oakhill Weight System

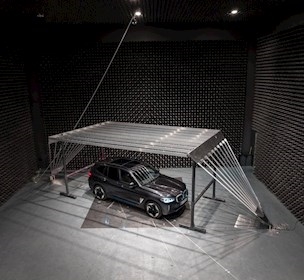

Our experts guided him through a structured, expert-driven compliance process—identifying gaps, refining the certification plan, and validating the product. From CE certification to vehicle compatibility checks and durability assessments, every requirement was addressed through extensive testing and hands-on collaboration. Throughout the process, Patrik was able to adjust software on-site, making refinements in real time to meet regulatory standards efficiently.

"FORCE Technology's experts treated my project with priority and care. No wait times and immediate expert response and feedback made a big difference to me – I didn't have time to wait, and the experts took the time needed to make sure my certification process ran smoothly and quickly," Patrik says.

Key Oakhill Weight System certification steps:

- CE certification – Ensuring regulatory compliance across European markets.

- Vehicle compatibility testing – Meeting electronic standards for modern trucks.

- Software and hardware validation – Verifying reliability under real-world conditions.

How the Oakhill Weight System works

- Wireless load monitoring – Real-time data from the truck's air suspension system

- Handheld touchscreen – A simple, intuitive interface built for truckers

- Optimised load control – Helps drivers balance their cargo for maximum efficiency

Related content

ABB's largest robot achieves EMC compliance

/Case

ABB collaborated with FORCE Technology to test and validate their largest robot for EMC compliance.

Electrified classic cars gain market access

/Case

Banke is testing electric driveline for EMC and electrical safety, ensuring market access.