Test and type approval of electronic automotive components

Enable market access with accredited electronic automotive component testing services.

Meet regulatory standards and enhance vehicle reliability and safety

Electronics are essential for various functions in today's vehicles. However, the dense electrical environment can cause electromagnetic interference (EMI), leading to malfunctions. Electromagnetic compatibility (EMC) testing ensures automotive components can operate effectively amidst electromagnetic disturbances, meeting regulatory standards and enhancing vehicle reliability and safety.

Type approvals for most types of automotive systems and components

We specialise in EMC, electrical safety and mechanical testing and can help you CE-mark or type-approve your products. This enables you to achieve quick, accurate, and safe market access, allowing you to sell products to car manufacturers.

Experienced automotive testing partner helps you all the way

Our team of experienced technicians and specialists can guide you through testing processes with a focus on necessary documentation. Whether you are a development engineer or test manager, we can help you on your journey from electronic automotive component development to market access.

Who accredits our electronic automotive component testing services?

- ILAC (International Laboratory Accreditation Cooperation) and DANAK (Danish Accreditation and Metrology Fund):

Signifies alignment with internationally recognised standards, enhancing credibility in assisting customers with CE-marking.

- KBA (Kraftfahrt-Bundesamt) Technical Service:

Offers expertise in regulatory compliance for product safety and performance under the German Federal Motor Transport Authority for E1-marking

- STA (Swedish Transport Agency) Technical Service:

Recognition emphasises commitment to Swedish government standards for E5 marking.

- Automotive Directive adherence:

Guides testing and certification processes, crucial for manufacturers seeking market access under the automotive industry's legal framework.

Examples of the automotive electronic components we test:

- Electronic Control Units (ECUs)

- Industrial trucks electronics

- Earth-moving machinery components

- Agricultural and forestry machinery components

- Aftermarket electronic equipment

- Vehicle Battery Management Systems (BMS)

- Electronic displays for industrial vehicles

FAQ

-

How can I find out which tests or standards apply to my automotive components?

To determine which tests or standards apply to your automotive components, you can consult with our team of experienced technicians and specialists. They can provide guidance tailored to your specific needs and help you navigate the complex regulatory landscape to ensure compliance with industry standards.

-

Why is EMC testing crucial for automotive components?

EMC testing ensures that electrical components meet specific standards, preventing interference issues and ensuring the safety and functionality of products used in vehicles.

-

To which standards does FORCE Technology test electronic automotive components?

Adhering to these standards is critical for automotive components as they collectively establish a framework for ensuring safety, compatibility, and performance in the complex and interconnected systems within vehicles:

- UN ECE Regulation No. 100 rev. 3 establishes standards for electromagnetic compatibility (EMC) and functional safety in vehicles, ensuring that electronic components meet specified criteria to prevent interference and maintain operational integrity.

- UN ECE Regulation No. 10 rev. 6 is a prerequisite for products used in vehicles to receive E-marking. This standard sets forth electromagnetic compatibility requirements, ensuring that electronic components within vehicles do not interfere with each other, guaranteeing safe and reliable operation.

- DS/EN 12895 outlines electromagnetic compatibility (EMC) requirements specific to industrial trucks.

- DS/EN ISO 13766-1 and DS/EN ISO 13766-2 establish standards for electromagnetic compatibility and functional safety in earth-moving machinery.

- DS/EN 14982 focuses on electromagnetic compatibility (EMC) standards for agricultural and forestry machinery.

- DS/EN 50498 defines standards for aftermarket electronic equipment in vehicles. Adhering to this standard ensures that electronic components added to vehicles after production meet specified criteria, preventing potential issues with compatibility and performance.

- CISPR 25 addresses radio disturbance characteristics in vehicles, boats, and internal combustion engines. Compliance with this standard sets limits and establishes measurement methods for protecting on-board receivers. Ensuring adherence to CISPR 25 prevents radio interference and maintains vehicle communication integrity.

- DS/EN 11451-1 and DS/EN 11451-2 focus on electrical disturbances in road vehicles. These standards cover general electrical disturbances and off-vehicle radiation sources, establishing criteria to mitigate electromagnetic interference in vehicles and ensuring their overall electrical integrity.

- DS/EN 11452-1 to DS/EN 11452-5 address radiated electrical disturbances in road vehicles. These standards set forth criteria for radiated electromagnetic interference, ensuring that vehicles operate without disruption due to external electromagnetic fields.

- DS/EN 11452-7 to DS/EN 11452-11 extend the standards for electrical disturbances in road vehicles to cover radiated interference in various frequency ranges. Compliance with these standards ensures vehicles are resilient to electromagnetic disturbances in their operating environment.

- ISO 16750-1 to ISO 16750-3 comprehensively address various aspects of road vehicle testing, covering general conditions, electrical, mechanical and climatic loads. These standards set criteria to ensure the durability and reliability of vehicles under diverse environmental and operational conditions.

- ISO 7637-2 and ISO 7637-3 focus on electrical disturbances caused by conducting and coupling in vehicles. These standards define criteria for testing and mitigating the impact of electrical disturbances on vehicle electronics, ensuring the overall reliability of electrical systems.

-

Can FORCE Technology assist with E-marking for automotive components?

Yes, FORCE Technology has extensive experience guiding automotive products through the requirements specification, relevant tests and public authority approval for E-marking.

We handle type approval for E5-marking with the Swedish Transport Agency and E1-marking with German authorities, being the only approved EMC laboratory for E1-marking in Scandinavia.

Our services include comprehensive EMC testing in compliance with UNECE Regulation 10, drafting reports, compiling documentation, and managing the approval process, ensuring a seamless route to E-marking.

Electrified classic cars gain market access

Banke is testing its electric driveline for classic Land Rovers for EMC, electrical safety, etc. The accredited tests ensure market access and knowledge for use in other green innovation projects.

Test of advanced digital actuators for hydraulic systems

We helped

Danfoss Power Solutions test a subcomponent of a hydraulic system that electronically controls how much oil comes out of a PVG. A PVG is a hydraulic, load-sensing proportional valve designed for optimal machine performance and maximum design flexibility.

Facility

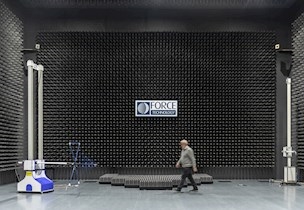

Explore our EMC testing facilities

Discover our advanced EMC testing facilities designed to accommodate a range of electronic products.

Case

Truck innovation needed certification for market entry

Auto certification is complex, so Oakhill Technologies turned to experts to speed approval.

Case

ABB's largest robot achieves EMC compliance

ABB collaborated with FORCE Technology to test and validate their largest robot for EMC compliance.