Laser welding: Fast and precise welding with minimal heat input

Laser welding delivers precise welds with high speed and low error rates. Laser welding saves you both time and money, with consistent quality and minimal need for reworks.

Laser welding opens new possibilities and offers many advantages

Laser welding is gaining more and more ground in the industry. Whether you are a blacksmith or machine shop, manufacturing company or entrepreneur, it offers you many advantages over traditional MIG/MAG and TIG welding in your production process.

To reap the full benefits, make sure to consider laser welding as early as possible during your product's development phase.

The Laser Centre is available to test your ideas and perform job-shop welding of your projects, so you do not need to invest in large and expensive laser welding equipment yourself.

The advantages of laser welding include:

- Automated welding processes

- High precision

- Consistent quality

- High welding speed

- Great flexibility

- Low failure rates

- Less scrapping

- Minimal deformation

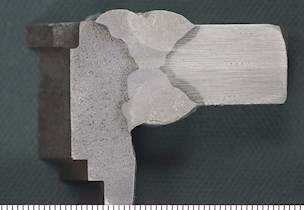

- Deep and narrow penetration

- Time savings

- Cost reduction.

Countless materials and applications are made possible by laser welding

Do you weld large material thicknesses or thin foils? Or somewhere in between? Laser welding can increase quality and productivity, allowing you to simultaneously achieve faster production and better products.

Laser welding allows you to weld many materials and workpieces, such as:

- Structural steel

- Stainless steel

- Alloys

- Aluminium

- Titanium

- Precious metals

- Plastics and polymers

- Complex geometries

- Very thin items, such as foils

- Substantial and thick components

- In close proximity to magnets

- Electronics

- Temperature-sensitive components, such as those near electronics and sensors.

Get started using laser welding in production

Whether you are looking to start manufacturing your laser-welded parts or you just need a few components weld-ed, we can help you with consultancy, prototyping, and production, including:

- Prototyping and testing

- Workpiece design and joint preparation

- Tolerances

- Welding procedures

- Choice of laser type (YAG, CO2, diode, disc, or fibre laser)

- Laser safety

- Pilot production.

In our lab, you can get help with everything from part design to actual pilot production. We have several consequential laser types with power levels ranging from 60 W to 16,000 W.

Contact us if you need more information about laser welding or if you need an item laser welded.

Facility

Laser welding is made available to the Danish industry

Services

WPS - Welding Procedure Specification

Get help designing the required WPS so your welders can perform the welding work.

Engineering critical assessment of welded structures

Is it safe to keep using a structure with flaws, without any risk of failure?

Laser safety - get the necessary risk assessment

Lasers are subject to EU directives and AT's regulation, and require regulatory risk assessment.