Cathodic protection of reinforced concrete

Cathodic protection reduces costs for future repair work and extends the life expectancy of your concrete structure. We assist in design, installation and service of the system.

Cathodic protection as an integrated part of the maintenance strategy for reinforced concrete

Many reinforced concrete structures suffer from premature degradation, most commonly caused by chlorides. Today, cathodic protection is used by many building owners as an integrated part of the maintenance strategy for reinforced concrete structures.

Therefore, many reinforced concrete structures are prepared for installation of cathodic protection already during the construction in contrast to earlier, when cathodic protection was only used as a method of repair. Cathodic protection efficiently stops ongoing corrosion and thus degradation of your structure

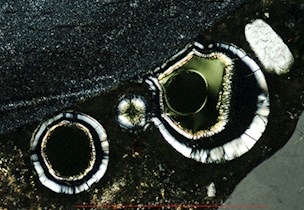

During installation under construction, parts, such as anode ribbon and reference electrodes, are embedded in the concrete of the reinforcement. Further, cables are drawn out from the structure before the concrete is cast, and we ensure that the reinforcement is electrically connected.

Chloride contamination degrades concrete

Chloride contamination occurs when the concrete structure is located in aggressive environments such as seawater, areas exposed to thawing salt and in swimming pools. There are several ways of stopping ongoing corrosion of steel reinforcement in concrete, which is contaminated by chlorides.The simplest and most direct solution is to break down the structure and replace it by a new and hopefully improved structure. Another procedure is to remove the concrete in which the chloride concentration is above the critical level, and replace it with uncontaminated repair material.

Instead of applying such drastic measures, you can install cathodic protection in your structure. This way you do not remove concrete or brickwork that is important to the strength of the structure, and you ensure that the building is maintained best possible.

Your choice of cathodic protection is crucial

Your choice of anode system, power supply and control units is crucial to a well-functioning system for cathodic protection. We provide a wide range of anodes and equipment for existing and new structures as well as customised power supplies and control units.We have developed and produced systems for cathodic protection, e.g. the durAnode® system, for a number of years, and we can now offer the 4th generation of the system.

Advantages of the durAnode® system:

- You get a complete system including e.g. tools and mortar.

- It does not increase the weight and size of the structure; this is particularly important if you e.g. build underground car parks or bridges.

- The system can be completely hidden and can therefore easily be used in e.g. historical buildings.

The cathodic protection is well-documented and in accordance with various European standards that define how efficient it is for preventing future corrosion.

Contact us if you want to know more about how you avoid corrosion in the reinforcement of your concrete structure.

Service agreement for systems for cathodic protection

If you have had a system for cathodic protection installed, you can also get a service agreement with us, and then you do not have to worry as to whether the system is working. We help you keep the system running and take care that your structure is protected against corrosion.Contact us if you would like a service agreement or to wish to learn more about how to protect your concrete structure.

Case

Building inspection prevents leaks in public pools

Services

Corrosion monitoring probes and measuring equipment

Minimise the risk of corrosion in your concrete construction by monitoring the steel reinforcement.

Materials examination and consultancy on constructions

Choose the right construction materials and get the right solution from the start.

Status assessment and failure analysis - concrete structures

Status assessment, failure analysis and quality control ensure durability and optimal renovations.