Performance evaluation

In order to ensure that the vessel will be performing according to contract, numerical calculations and still water tank tests are performed with the propulsion system as per the real vessel.

We possess the equipment to perform model tests of all types of propulsion systems ranging from conventional propellers to advanced waterjet systems and POD propulsion systems. Our equipment and experience covers the range from one to five propulsion units installed.

The tests are performed in our large deep water towing tank or in our shallow water manoeuvring basin.

The typical scope of work includes:

- resistance tests

- self propulsion tests

- trim tests

- added resistance tests in waves

- flow visualisation tests (streamline tests & tuft tests)

- wakefield measurement

- cavitation tests

Numerical speed and power prediction

In the early design phase during which the hull lines are reviewed and optimised, it is highly important to be able to predict the speed of the ship and the required power accurately.

Based on our large database of resistance and propulsion data, we have developed a prediction tool. By means of this program, we assist ship designers and naval architects with speed and power predictions.

The predictions are based upon all the resistance and propulsion data obtained through our many years of service. The idea behind the database is to search for ships similar to the one considered in the new design project and use the existing results to guide the new speed and power prediction. When working with the database, it is therefore important to identify the characteristic parameters for the considered type of ship and use these parameters to search for parent ships matching the new project design.

The prediction tool can perform predictions based upon main parameters and coefficients only. Today we normally combine the database tool with advanced CFD calculations when the exact hull form is available in a digital format to prepare the best possible prediction.

When CFD calculations are involved, the resistance for the new design is typically calculated for a number of speeds, and the results are used to calibrate the output from the database method to the data for the actual hull form.

Facility

Towing tanks

Services

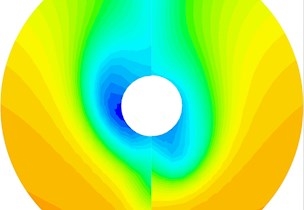

Detailed flow studies

Detailed flow studies can be used in the design phase or at modifications of an existing vessel.

Dynamic Positioning (DP) investigations

The dynamic positioning system allows the vessel to operate at sea without mooring or anchoring.

SeaTrend: Verified hull & propeller insights

Track hull and propeller performance with real-time, verified data for greener shipping.