Accredited tests of retroreflective materials and sheeting

Retroreflective materials and sheeting are used in a variety of products and applications for safety reasons. Obtain verification of compliance according to relevant standards with accredited testing.

Retroreflective materials, with their unique ability to redirect light back to its source, have emerged as indispensable assets in enhancing visibility and safety. These versatile materials find application in a myriad of industries, from traffic and transportation to consumer products, aerospace, and beyond. As these materials become more dominant in our daily lives, the need for comprehensive testing has grown exponentially.

Measuring reflective sheeting and retroreflective materials is important for several reasons:

- Performance evaluation

Reflective sheeting and retroreflective materials are used in various applications, such as road signs, vehicle markings, high-visibility clothing, and safety products. Measuring their reflective properties allows for the evaluation of their performance and compliance with specific standards or regulations. This ensures that the materials meet the required visibility and safety standards.

- Quality control

Manufacturers of reflective sheeting and retroreflective materials need to measure and control the quality of their products. By conducting measurements, manufacturers can ensure that the materials meet the desired specifications, such as the minimum coefficient of retroreflection or color characteristics. This helps maintain consistency and reliability in the production process.

- Research and development

Measuring reflective sheeting and retroreflective materials is crucial for research and development purposes. It allows researchers to compare different materials, coatings, or manufacturing techniques to improve performance, durability, and cost-effectiveness. Accurate measurements provide valuable data for optimising and innovating these materials.

- Safety standards compliance

Reflective sheeting and retroreflective materials are often regulated by safety standards in various industries. For example, road signs and markings must meet specific retroreflectivity requirements to ensure visibility and driver safety. Measuring these materials ensures compliance with the standards and helps identify any non-compliant products that may pose risks to public safety.

- Performance maintenance

Over time, reflective sheeting and retroreflective materials may degrade or become less effective due to weathering, dirt accumulation, or damage. Regular measurements can help assess their ongoing performance and identify when maintenance or replacement is needed. This is especially important for applications where visibility is critical, such as traffic control or personal protective equipment.

Ensuring optimum retroflection with specific test parameters

Road markings must contain small glass beads, and the sign film material must contain glass beads or microprisms to enhance the reflection or retroreflection to a level that can assist drivers.

Measuring reflective sheeting and retroreflective materials, various instruments are needed and accredited methods are described in standards depending on the application. Test requires calibrated instruments and approved test methods. These tools and methods quantify parameters like coefficient of retroreflection, color characteristics, luminance, and brightness, providing objective measurements for evaluation and comparison.

We offer accredited and impartial testing of various parameters, including:

Standards for safety clothing

- EN 471 / EN 20741. High-visibility warning clothing for professional use – Test methods and requirements / High-visibility clothing – Test methods and requirements

Standards for road traffic signs

- EN 12899. Fixed, vertical road traffic signs. Most relevant is Part 1: Fixed signs and Part 4: Factory pro-duction control

- ASTM E1709. Standard Test Method for Measurement of Retroreflective Signs Using a Portable Retroreflectometer at a 0.2 Degree Observation Angle

- ASTM E2540. Standard Test Method for Measurement of Retroreflective Signs Using a Portable Retroreflectometer at a 0.5 Degree Observation Angle

Other related standards

- DIN 67250. Retroreflecting materials for traffic safety – Photometric minimum requirements for retroreflective sheetings

- ASTM D 4956. Standard Specifications for Retroreflection Sheeting for Traffic Control

- ASTM E809. Standard Practice for Measuring Photometric Characteristics of Retroreflectometers

- ASTM E810. Standard Test Method for Coefficient of Retroreflection of Retroreflective Sheeting Utilizing the Coplanar Geometry

Standards for measurement of retroreflective pavement marking material

- EN 1436. Road marking materials – Road marking performance for road users

- ASTM E1710. Standard Test Method for Measurement of Retroreflective Pavement Marking Material with CEN-prescribed Geometry using a Portable Retroreflectometer

- ASTM E2177. Standard Test Method for Measuring the Coefficient of Retroreflected Luminance (RL) of Pavement Markings in a Standard Condition of Wetness

- ASTM E2302-03a. Standard Test Method for Measurement of the Luminance Coefficient Under Diffuse Illumination of Pavement Marking Materials Using a Portable Retroreflectometer

- ASTM E2832. Standard Test Method for Measuring the Coefficient of Retroreflected luminance of Pavement Markings in a Standard Condition of Continuous Wetting (RL-2)

Other related standards

- ASTM E2366. Standard Test Method for Measurement of Daytime Chromaticity of Pavement Marking Materials Using a Portable Reflection Colorimeter

- ASTM E2367. Standard Test Method for Measurement of Nighttime Chromaticity of Pavement Marking Materials Using a Portable Retroreflection Colorimeter

Please do not hesitate to contact us to learn more about how you can verify the reflective sheeting and retroreflective materials of your products to ensure performance, quality, safety and comply with standards and regulations.

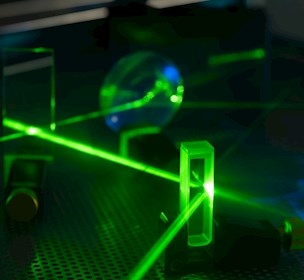

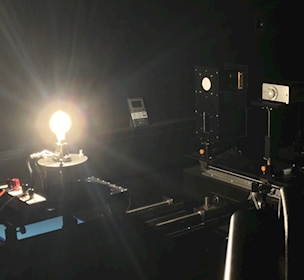

Photonics, light, and optics laboratories

/Facility

Accredited testing of e.g. sensors, light sources, lighting products and retroreflective materials.

Accredited light measurement of light sources

/Service

Get tested and verified if your light sources and lighting systems meet requirements and standards.

RoadSensors retroreflectometers

/Service

Monitor the performance of road markings and traffic signs to ensure road traffic safety.