Mechanical test of large components

Full-size structures can be exposed to static and dynamic multi-axial loads or fatigue testing and applied with simulated loading from e.g. waves or wind.

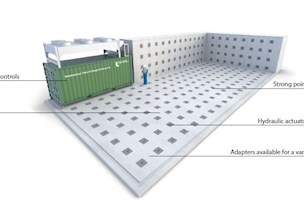

High capacity mechanical test bench

Testing of large components and structures can be performed on the mechanical test bench at Lindø Component and Structure Testing A/S. The size and capacity of the test bench enables testing with realistic forces.

Full-scale testing can supplement the testing of sub-systems and components, where complex mechanical or structural systems can be tested in near operational conditions.

Outstanding testing capabilities

Exposing full-size structures to multi-axial loads is one of the highlights of the facilities capabilities. Simulated loading from waves, wind or other operational conditions are straightforward and realistically applied in various flexible testing setups.

Static and dynamic extreme loads or fatigue testing can all be handled by the test bench and the state of the art hydraulics and control system.

In cooperation with our clients, we aim to measure the characteristics and responses needed for evaluation of each structure and systems.

Customising data collection

Standard or customised data recording can be conducted utilizing a variety of gauges and sensors, e.g. strain gauges, displacement sensors, load cells, temperature, etc. Our specialists will be able to assist you in selecting and installing the correct instrumentation for all test set-ups.

Documentation of durability

We work with two different testing scenarios:

- You can lead the test and the subsequent documentation of results yourself, with us as operator of the facility.

- We can provide a turn-key service and operate the facility and prepare a report with your required documentation of test results.

No matter which setup is chosen the testing scenario will be conducted in close collaboration with you to comply with test standards and/or the requirements of the client. By having us prepare the documentation for the test we ensure that the delivered documentation meets the requirements present in the relevant standards.

Supplementary examinations and reports can also be conducted, e.g. results from metallography, calculation verifications, S-N curves, corrosion studies, etc.

The ability to test large components or full-scale systems will give you the necessary verification to ensure your system meets the high demands of its operating environment.

Strategic partnership for the benefit of industry

FORCE Technology has assisted industries world-wide with challenges relating to materials and systems for more than 75 years. Our extensive experience is one of the things our customers value most.

We are continually striving to develop advanced materials and testing solutions for our customers. Therefore, FORCE Technology has formed a strategic partnership with Lindø Offshore Renewable Centre (LORC) in order to offer tests of large components and systems.

The partnership between LORC and FORCE Technology has resulted in establishing Lindø Component and Structure Testing A/S. The new facility for developing and testing of large components and structures has been established at Odense Port, Denmark.

Facility

Mechanical tests of large structures

Related services

Climatic test of large components

/Service

Test of large components, structures and functional systems under realistic conditions.

Mechanical testing: industrial products and components

/Service

Ensure durability, safety and reliability – under both normal and extreme conditions.

Mechanical testing – vibra-tion, shock, transport etc.

/Facility

Mechanical testing of your products and components. Vibration, shock, transport testing etc.