AM Link: Your network for 3D printing

AM Link is your shortcut to 3D printing in Denmark. The network is focused on helping you leverage the many pos-sibilities of 3D printing, regardless of technology, materials and methods.

FORCE Technology's AM Link is a partner network with both national and international partners and companies within AM (additive manufacturing).

Get started with 3D printing with AM Link

The network's partners are specialists in their respective fields. They can help you start your project and give you access to 3D printers. You can print prototypes and actual production runs, and you can get help with issues related to 3D printing and AM.

Assistance is available to help you:

- Determine whether 3D printing is suitable for your project

- Choose the optimal 3D printing method and material

- Optimise the design and topology of your item

- 3D-print metals, polymers, composites, concrete and ceramics

- Perform 3D scans of printed items

Improving sustainability using 3D printing for repairs and lifetime extension

If you want to extend the life of a component or repair a large and expensive component, consider whether you can apply 3D printing or AM to the part.

Get help via AM Link for tasks like these:

- Estimating production times and costs

- Choosing a material and methodology

- Renovating worn surfaces

- Protecting surfaces from corrosion

- Quality assurance and documentation

Repairing or extending the lifetimes of your components can often save both time and money. Get help with sustainability calculations for your organisation's ESG reporting.

Quality control for 3D-printed parts

Once you have 3D-printed a part, you must verify that it meets specifications and associated standards.

Quality control may involve:

- A 3D CT scan or ultrasonic (UT) inspection

- Testing, analysis and tensile tests for verification of mechanical properties

- Documentation of whether your product meets specifications and standards.

Contact us, and we will help you find the most qualified assistance via AM Link to complete your 3D project quickly and safely.

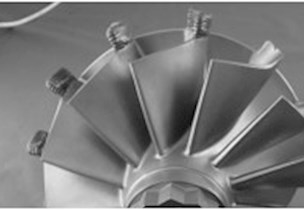

Examples of 3D-printed jobs

Surface treatment with rubber using AM techniques

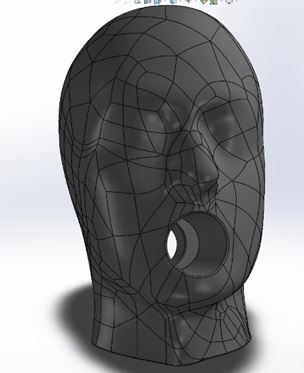

Rapid 3D manufacturing of test heads for PPE testing

Due to a shortage of test heads, AM Link partner 3D Printhuset A/S scanned a test head in just a few hours andcreated a CAD file to print more test heads.