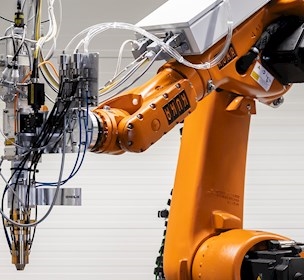

3D printing & AM: print jobs, testing, documentation and consulting

Get started with 3D printing and AM (additive manufacturing) to extend the lifetimes of your components and obtain documentation to showthat your 3D-printed parts meet requirements.

Whether you are a novice or an experienced 3D printer or AM (additive manufacturing) professional, you may need help printing a part or documenting that your printed part meets specifications, requirements and standards. You may also need the advice of a consultant on 3D printing and help getting started using the technology.

Get help using 3D printing and AM

If you are a business or individual who needs to test out 3D printing or AM ideas or repair expensive components, help is at hand.

Assistance is available to help you:

- 3D-print prototypes or small production runs

- Repair items, such as spare parts

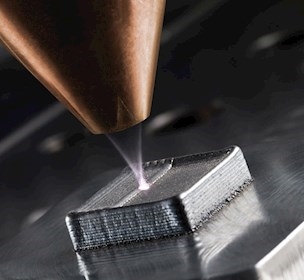

- Give components new and reinforced surfaces

- Extend the lifetimes of components.

You can test your ideas without the significant investment into your own 3D printing system or AM facility.

3D printing is a production method that consumes fewer resources than traditional methods, increasing the sustainability of your production. Often, this can be done within Denmark, avoiding expensive, time-consuming and carbon-intensive transportation from abroad, which is usually needed for critical spare parts that are traditionally manufactured.

Test and document the quality of your 3D-printed parts

Once you have printed a component, you must document that it meets your specifications or requirements and standards in the application where the component will be used.

Obtain quality assurance and mechanical testing for your 3D-printed items with:

- Non-destructive tests (NDT), such as:

- CT scanning

- X-ray

- Roughness measurement

- Penetrant examination.

- Destructive tests (DNT), such as:

You can also have an item inspected for possible hidden defects, such as:

- Cracks

- Delamination

- Porosity.

This ensures that your 3D-printed parts and surfaces comply with all requirements and standards, allowing you to document product properties and inspire confidence in product durability.

Consulting within 3D printing and AM

3D printing and AM offer many opportunities to generate prototypes and quickly start a new development project. Before you get started, there are several factors to consider:

Get the advice of a consultant on 3D printing and AM when it comes to:

- Choosing the right material with the desired properties

- Choosing the optimal 3D printing method and technology

- Choosing a print strategy

- Clarifying the need for support structures

- Topology and design optimisation.

Standards in 3D printing and AM

Suppose you will deliver 3D printed parts to the industry. In that case, you must be aware of the relevant 3D printing standards to ensure that your project meets quality, safety and functionality requirements.

Standards such as ASTM, ISO, and sector-specific regulations are essential in defining how 3D printing can be used safely and effectively in prototyping and production.

FORCE Technology participates in national and international standardisation work within 3D printing and AM standardisation in all relevant aspects, from production and quality assurance to HSE and operator training for 3D printing machines.

Contact us if you need help getting started with 3D printing or need to document the quality of your 3D-printed parts.

Related content

X-ray inspection ensures flawless AM parts

/Case

The architects from BIG use 3D metal printing

/Case

A whole new world has opened up for the BIG architects, who see great potential in 3D metal printing

AM versus CNC machining

/Article

Additive manufacturing saves money.

Article