Remanufacturing and repairing metal parts for enhanced sustainability

Remanufacturing and repairing metal parts extends component lifetimes, saves money, supports sustainability, and enhances your green credentials and environmental footprint.

What is remanufacturing?

Remanufacturing is a designation for intelligent, industrial methods of renovating, repairing or rebuilding metal components, including both very small and very large metal objects.

Clever methods for remanufacturing and repair include:

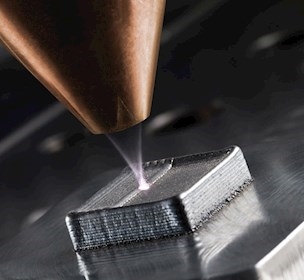

- 3D printing

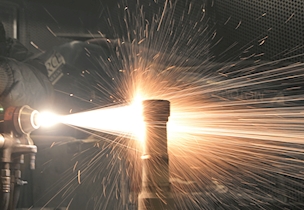

- Thermal spraying

- Metallisation

- Laser cladding

- Surface treatment

- Arc spraying

- Plasma spraying.

What can you use remanufacturing for?

If you have been unfortunate and shaved off too much of a metal part, or if a part's chrome plating has peeled off, you do not have to scrap the part. Instead, you can repair it by remanufacturing it.

You can use remanufacturing to:

- Repair a damaged or worn metal surface

- Rebuild a metal surface

- Restore incorrectly machined metal surfaces

- Salvage components with surface defects

- Add a new wear layer.

Remanufacturing makes your metal parts better and stronger

Remanufacturing can often make your metal components as good as new. They can often come out better than their original state, as the process also allows you to optimise their design and quality.

You can customise the new surface to be more durable, corrosion-resistant and robust than the old one. This way, your components come out in a state superior to when they left the factory, with enhanced lifetimes and performance.

Remanufacturing and repairing metal parts increases sustainability

When you choose to remanufacture or repair your metal parts instead of buying new ones, you actively promote sustainability and support the circular economy. You also reduce the need for raw material extraction and production manufacturing of new components, which often require energy-intensive processes. Furthermore, remanufacturing can be performed locally, minimising the environmental impact of transportation.

With remanufacturing and repair, you can save:

- Time: No lead times for manufacturing of new components.

- Money: Repairs and remanufacturing are often more economical than new production.

- Materials: Reusing existing materials reduces the requirement for new virgin resources.

- Energy: Remanufacturing typically uses less energy compared to producing new parts.

- CO2: Reducing energy consumption and transport reduces CO2 emissions.

Remanufacturing gives your green credentials a boost

When you use remanufacturing or have metal parts repaired with us, we can also help you with a green calculation that shows how much CO2, energy and materials you save by choosing not to have a brand-new component manufactured. You can include this calculation in your green records as evidence of your company's sustainability efforts and responsibility.

When you extend the lifetimes of valuable components, you also reduce the need to extract new resources and minimise waste. We can help you optimise component quality and performance with advanced process and materials knowledge while protecting the environment.

Remanufacturing for metal parts of all sizes

We have large-scale 3D printing facilities capable of handling parts up to 4 metres in length with a width of 1 metre and a weight limit of 3 tonnes.

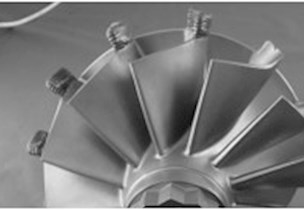

This allows us to restore advanced metal components, such as:

- Shafts and bearings from systems like engines and power plants

- Pipes and fittings, even internally

- Food processing machinery

- Heat exchangers – as an alternative to chrome plating

- Pistons, turbochargers and other components for marine engines.

On a smaller scale, you can get valve heads refurbished, e.g. for truck engines, where we can optimise the process and prevent heat-induced deformations.

In general, remanufactured or repaired parts can be put back into operation without straightening and re-alignment measures, as the induced heat does not deform them.

Contact us for help on how you can best use remanufacturing to repair your metal parts.