The new EN 45560 – a practical approach to circular design

How can you design electronic products that last longer and are easier to repair and recycle? The new EN 45560 standard provides a practical approach to circular design.

Sustainable design, production and operation of electronic equipment are evolving rapidly. EU directives and regulations on ecodesign are some of the main drivers behind this development.

The general ecodesign requirements contain no technical details – these are specified in the harmonised EN standards linked to the overarching EU requirements.

One of the latest standards in this area is EN 45560, published in November 2024. This article provides insight into how the new standard can be applied in practice, illustrated by a completed case study.

Nordic Firefly translates EN 45560 into sustainable product design

Nordic Firefly A/S is a Danish company that develops solar-powered LED lighting products. These products are both intelligent and efficient – even during periods of limited daylight and long winter nights.

As part of the completed result contract “Long live products and materials”, Nordic Firefly kindly made case studies available.

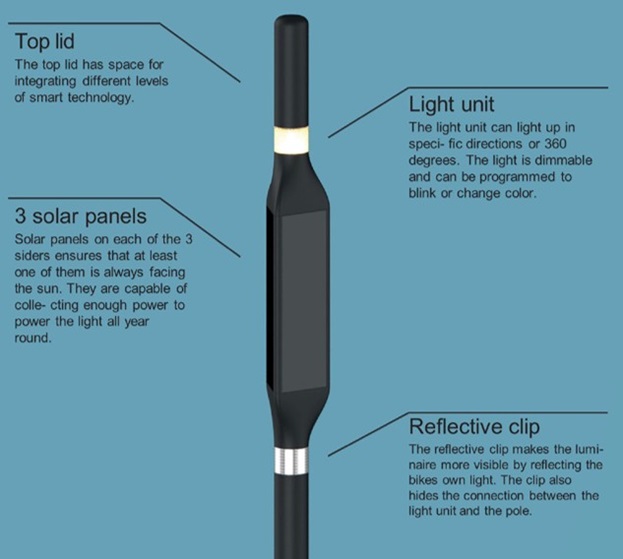

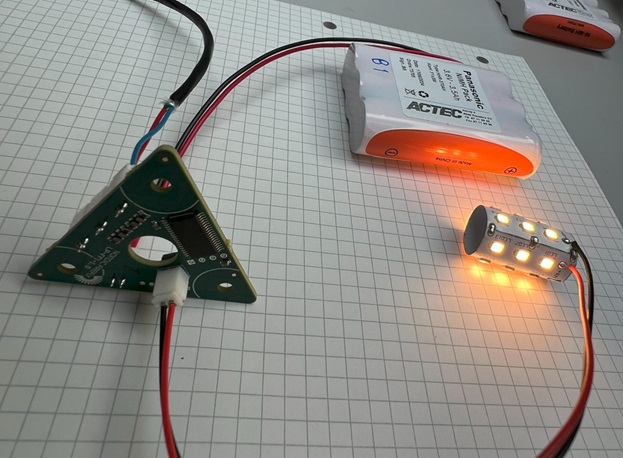

The case described here involves the Light Post – a relatively simple lamp designed, among other things, to illuminate dark cycle paths. In short, the lamp consists of: 1 battery pack, 3 solar cells, 1 small PCB with electronics, 1 LED light source and 1 enclosure. Figure 1 below shows the product’s main components:

EN 45560: a gateway to circular design

The EN 45560 standard, “Method to achieve circular designs of products”, can be seen as a gateway to the other 9 standards in the EN 455xx series. It is therefore a useful starting point for working with ecodesign.

Figure 2 from EN 45560 is shown below and provides a good overview of the methods described, including references to other relevant standards in the series.

One of the key elements in EN 45560 is the ability to handle trade-offs – the compromises that inevitably arise when different sustainability requirements conflict. The standard contains an entire section on this topic (6.5: Trade-offs considerations in circular product design). The case described here includes examples of specific trade-offs.

How can EN 45560 be applied in the Nordic Firefly case?

The following illustrates how EN 45560 can be applied in practice in the Nordic Firefly case. Focus is on the most important points, so not all aspects of sustainable design are included.

“Consume less input resources to make a product”

At the top of figure 2 from EN 45560 is the statement “Consume less input resources to make a product”. As mentioned, the lamp is built as simply as possible with a minimum number of components.

Few different materials are used, and the quantity of materials is minimised – while still ensuring that the lamp has sufficient mechanical robustness to withstand “moderate vandalism”.

If you want to explore the use of critical raw materials, EN 45558 and the EN/IEC 62474 standards and databases referenced therein can be used.

“Reliable products that last longer”

The second level of figure 2 from EN 45560 states: “Reliable products that last longer”. Here, Nordic Firefly has opted to “overdimension” the battery capacity compared to the minimum needed to meet short-term functional requirements. This increases the margin and – all other things being equal – extends product lifespan.

The company has also chosen to use several LED components in the light source (18 or more), which reduces the load on each individual LED and provides better conditions for thermal management. Both measures – all else being equal – contribute to a longer product lifetime.

As part of an analysis of possible condition monitoring for each lamp, an ageing test was carried out on the electronics (PCB) and light source at +110°C. If this is regarded as a basic lifetime test, and the results are combined with the methods and data described in SPM report 179 “Acceleration factors and accelerated life testing”, the test indicates a lifetime of just over 8 years for the electronics and LED light source at an average ambient temperature of +20°C.

The test was conducted according to the principles described in EN 45552, which references IEC 62506 for accelerated life testing.

“Product reuse, repair, upgrade”

The third level in figure 2 from EN 45560 covers “Product reuse, repair, upgrade”. Nordic Firefly designed the lamp so that it can be disassembled into modules using standard hand tools.

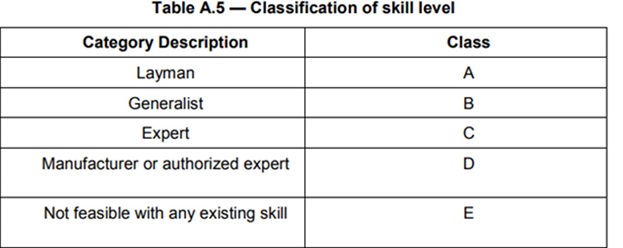

EN 45554 includes examples of tools classified as standard hand tools. This means the company meets “Skill level classification class B” in EN 45554, as a “generalist” can disassemble and replace modules. However, updating the lamp’s firmware requires a “manufacturer or authorized expert class D”.

See figure 4 for the definition of skill levels.

The modules (battery, electronics, light source and solar cells) are connected using connectors. This supports repair and upgrade efforts but can reduce reliability, as electrical connectors are known to be a weak point. This is a good example of one of the trade-offs highlighted in EN 45560.

“Remanufacturing”

The ease of disassembling the lamp into modules also means it scores highly in terms of “remanufacturing” – a concept covered by EN 45553.

“Parts recovery” and “Materials recycling”

The fifth and sixth levels in figure 2 from EN 45560 concern “parts recovery” and “materials recycling”. Due to Nordic Firefly’s design choices, the product can easily be separated into functional modules and the various materials used in the enclosure at end-of-life.

The electronics (PCB) is not easy to disassemble into components, parts or materials with current technologies and methods. This applies to all products that use PCBs. However, the mass of the PCB in this lamp is minimal compared to the overall product, meaning the electronics score well in terms of EN 45556 and EN 45557. In contrast, heavier components such as the batteries have a negative impact.

EN 45560 as a tool for sustainable product design

The Nordic Firefly case demonstrates how EN 45560 can be used as a practical tool to optimise sustainable design.

The standard’s methods help balance material consumption, product longevity and recyclability, while also managing necessary design trade-offs. Thus, for companies aiming to develop more circular products, EN 45560 can be a valuable starting point.

This article was previously published in the SPM Magazine, March 2025.