Sustainability screening – assistance in optimising the sustainability of your products

Get your mechanical, electromechanical or electronic product reviewed early in the development process with an impartial sustainability screening.

When developing new products, integrating sustainability into the design can be challenging. Focus is often on functionality, development time and product pricing. Through a sustainability screening, we can help you incorporate sustainability from the start of the development process.

The screening is optimally carried out early in the development process since this allows for any necessary changes to be made without significant costs.

The target group for the sustainability screening includes developers of mechanical, electromechanical, or electronic products.

Assessment of sustainability based on your goals

A sustainability screening provides you with:

- A qualitative assessment of how sustainable your product is in relation to relevant methods and standards

- An overview of your sustainability potentials and challenges

Specific focus areas in the sustainability screening

The assessment of your products' sustainability may include the following areas:

- Regulatory requirements

- Lifetime and reliability of the design, focusing on hardware, software and mechanical solutions

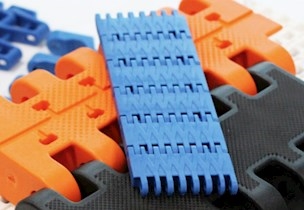

- Choice of materials and resource consumption

- Use of recycled materials, components and parts

- Possibility for product life extension (re-manufacturing, modularity, repair and software updates)

- Limitation of single-use products or accessories

- Possibility for disassembly

- Optimisation of production processes

- Packaging design

- Possibility for re- and upcycling

- Challenges related to Life Cycle Analysis (LCA)

- Integration of batteries

Solid technical foundation for the sustainability screening

The screening is based on relevant models and standards, e.g.:

- CIRCit

- IEC/EN 60601-1-9: "Medical electrical equipment - Part 1-9: General requirements for basic safety and essential performance - Collateral Standard: Requirements for environmentally conscious design"

- prEN 45560: "Methods to achieve circular designs of products"

Holistic insight into the sustainability potentials of your products

The screening takes place as a meeting between representatives from your company and relevant specialists from FORCE Technology. Since the specialists have various fields of expertise and experience, you gain a holistic insight into the product's sustainability and potentials.

We review the product idea, mock-up, prototype or your finished product to assess the level of sustainability. The assessment includes points that can typically pose challenges, and we suggest possible solutions.

Please contact us to evaluate how sustainable your product already is – and its sustainability potential.

How do you prepare for the sustainability screening?

Before the screening meeting, we ask you to share the following information about the product with us:

- General description of the product

- Description of the chosen materials

- Expected design life

- Planned maintenance to achieve the desired design life

- The length of the material should allow it to be read in half an hour.

Since the screening is most valuable early in the development process, we understand that some of this information may only be available to a limited extent.

Related content

Case: Take-back and the EU’s Digital Product Passport

/Case

Danfoss advances sustainable product development

/Case

Danfoss had its efforts in sustainable product development assessed to meet circularity goals.

In IoT startup Acembee, sustainability is no buzzword

/Case

Acembee had the sustainability of its IoT solution screened. This gave a more competitive product.

Sustainable product development

/Service

Sustainable product development – get help for a systematic product development process.

Designing sustainable products

/Page

We need to rethink how we design products to make products last longer.

Long live products and materials

/Project

Sustainable design and new materials must equip Danish industry for a circular economy.

LCA – Assess environmental impact of your product

/Service

Document and communicate your product’s environmental impact with a complete life cycle assessment.