Ammeraal Beltech optimises take-back and prepares for the EU's Digital Product Passport

Conveyor belt manufacturer has refined its take-back programme and prepared for the EU's Digital Product Passport. The result is a significant reduction in CO2 emissions and greater competitiveness.

Is it possible to optimise a take-back solution to create value here and now while also preparing for future EU requirements? In collaboration with FORCE Technology and tech startup PUFIN-ID, Ammeraal Beltech has shown that the answer is yes.

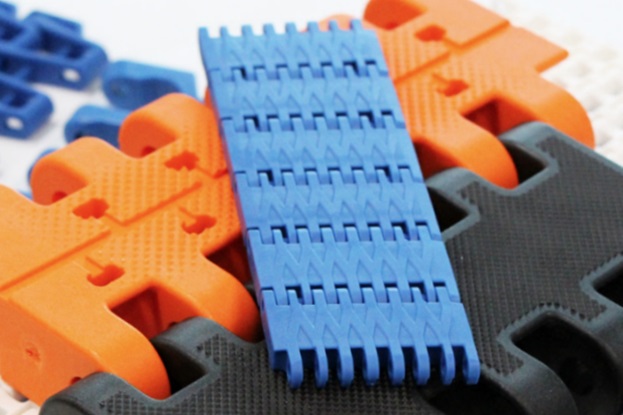

Ammeraal Beltech produces conveyor belts and other belt solutions for use in a wide range of industries. The company's products ensure efficient transportation of goods in contexts ranging from food production facilities and airports to logistics hubs and the automotive industry.

Take-back: from waste to resource

"For us – and for our customers – creating truly sustainable products that can be recycled is important," says René Rønning, Ammeraal Beltech's Program and Market Director.

As part of a circular approach, Ammeraal Beltech has long focused on internally recycling its plastic products. The company has additionally developed a take-back programme, whereby customers can return used products to be washed, sorted, and separated into their original materials. These used components can then be recycled into new products.

At a take-back network meeting, Ammeraal Beltech approached FORCE Technology to discuss ways in which the take-back programme could be further developed.

"We knew that take-back would be an important part of our future business model, but we were lacking a structured solution and real-world knowledge," Rønning explains.

The Digital Product Passport: data-driven transparency throughout the value chain

Simply accepting used products from customers is not enough to create a functional take-back programme. In Rønning's words, "The take-back model simply doesn't work optimally without a traceability mechanism."

This is where the EU's Digital Product Passport comes in. As part of the Ecodesign regulation, the Digital Product Passport provides transparency around the composition, environmental impact and recyclability of products. Product passports will make it easy for other actors in the value chain to access and retrieve this data.

The requirements for the Digital Product Passport and the data points to be included in it have not yet been finalised. However, the plastics industry will likely be among the first to be subject to the requirements.

Despite these unanswered questions, Ammeraal Beltech and FORCE Technology decided to include the Digital Product Passport in the project to improve the company's take-back programme – partly because the structured approach to data can provide value here and now, and partly because staying ahead of EU requirements can provide a significant competitive advantage. The relevant data points can always be added later, as the specific requirements become known.

O-KEY: flexible and ultra-secure digital ID for authenticity, traceability and digitalisation

To ensure that the necessary recycling and material data can be easily recorded and tracked, Ammeraal Beltech needed a technology that can link physical products to digital data. PUFIN-ID provides a technology called O-KEY, which may become a key component in Ammeraal Beltech's work with the Digital Product Passport.

PUFIN-ID's solution works somewhat like a miniature QR code that can be attached to a component or product. Physically consisting of microscopic titanium particles, the solution is a unique digital ID that cannot be copied.

With O-KEY, every tagged product can be tracked and authenticated throughout its life cycle while also serving as legally valid proof, regardless of where the product is on its journey. The data can be easily read using a smartphone, making the solution user-friendly and accessible in any situation.

Companies can customise the data carried by O-KEY according to their needs – for example sustainability information, production data or other relevant documentation. This allows manufacturers and consumers to verify authenticity and gain insight into critical product information.

Reducing CO2 emissions: a key sales parameter

For Ammeraal Beltech, staying at the forefront of the green agenda is a big deal, given how crucial it has become for their customers.

"As a matter of fact, customers no longer start by asking about prices. Now, the first question is about how much we've reduced a product's CO2 emissions," Rønning says. "Customers also have to find all of these reductions in CO2 emissions for their ESG reports. So, it's a chain reaction, really."

Rønning is confident that this work on the take-back programme and documented recyclability will bolster Ammeraal Beltech's competitiveness. "We're a first mover in the sector, so that's probably why we're taking some flak on behalf of the other players. That's just the way it is, though. CO2 is simply the new currency."

A green model for new products and markets

Ammeraal Beltech's take-back project is initially focusing on three product groups, but its scope is continuously expanding, and the project may become part of all upcoming product launches. In fact, the entire group is looking at the project as a model for how to handle take-back programmes and the Digital Product Passport.

"Our collaboration with FORCE Technology has been great. It's been almost like been a green wake-up call for us, opening our eyes to things we didn't have the first idea about," Rønning says.

In addition to extending the lessons learnt from this project to new product groups, Ammeraal Beltech is also thinking about markets beyond the EU.

"We are an EU company, but at some point, we'll probably start doing take-back in Asia and the US, where we already have a factory. What will we need to have in mind there? Asking FORCE Technology is the obvious choice for us. After all, you already know the opportunities and challenges we're facing. This project is most likely just the beginning of our partnership," Rønning concludes.

Danfoss advances sustainable product development

/Case

Danfoss had its efforts in sustainable product development assessed to meet circularity goals.

In IoT startup Acembee, sustainability is no buzzword

/Case

Acembee had the sustainability of its IoT solution screened. This gave a more competitive product.

Sustainability screening – get help early

/Service

Get your mechanical, electromechanical or electronic product reviewed early in development.

Designing sustainable products

/Page

We need to rethink how we design products to make products last longer.

LCA – Assess environmental impact of your product

/Service

Document and communicate your product’s environmental impact with a complete life cycle assessment.