Danfoss accelerates its sustainable product development

Danfoss has brought in external specialist expertise to assess its efforts in sustainable product development. The company is now even better equipped to meet its ambitious circularity goals.

As a global leader in energy-efficient solutions, Danfoss aims to contribute to society's green transition. Consequently, the company has set ambitious climate and circularity goals for its products, such as aiming for carbon neutrality by 2030.

Danfoss strives to become the preferred technology partner for customers aiming to reduce carbon emissions by improving energy efficiency and machine productivity, lowering emissions and promoting electrification.

Continuous improvement in sustainability

Overall, Danfoss aims for new products to continuously achieve a stronger sustainability profile than their predecessors.

Starting from the product development phase, Danfoss prioritises ecodesign and a high degree of circularity and sustainability. In this process, the company has involved external expertise to ensure good operational tools. These tools must be well-considered, up-to-date and effective, ensuring that Danfoss complies with the EU's ecodesign regulation.

The collaboration fundamentally focused on assessing and optimising the tools according to the latest standards, legislation and expert practices from various research projects.Lina Psarra / Circularity Lead, Danfoss

Optimised tools for sustainable and circular product development

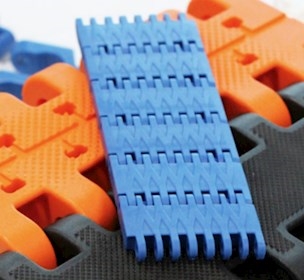

In collaboration with FORCE Technology, two tools in particular – RE:CIRC and DCI (Danfoss Circularity Index) – have been optimised. This has enabled Danfoss' to assess and improve new products in terms of sustainability and circularity.

"The collaboration fundamentally focused on assessing and optimising the tools according to the latest standards, legislation and expert practices from various research projects," explains Lina Psarra, Circularity Lead at Danfoss.

RE:CIRC – focus on the product development process

Danfoss' RE:CIRC tool can help identify areas with the greatest potential for improvement in the product development process.

RE:CIRC assesses a product's sustainability by ranking it against the 30 guidelines described in Danfoss' sustainable design guide. Divided into the overarching categories Rethink, Reduce and Recirculate, the guidelines include reducing material consumption, making spare parts accessible and avoiding materials that complicate recycling.

The tools we developed together essentially make circularity and sustainability more operational. Many companies have goals and KPIs, but when it becomes operational and relates to tools and processes – both in the development process itself and ongoing thereafter – it can truly make a difference in the environmental impact of products.Christine Bang Kragelund / Business Development Manager, FORCE Technology

Built on a strong foundation

While Danfoss already had a solid foundation in its tools to promote circularity and sustainable product development, the collaboration with FORCE Technology revealed opportunities to strengthen these tools. The collaboration particularly focused on prioritising Danfoss' focus areas based on environmental significance. Danfoss received advice on formulating ecodesign criteria and managing trade-offs.

"The tools we developed together essentially make circularity and sustainability more operational," says Christine Bang Kragelund, Business Development Manager at FORCE Technology. "Many companies have goals and KPIs, but when it becomes operational and relates to tools and processes – both in the development process itself and ongoing thereafter – it can truly make a difference in the environmental impact of products."

Expert knowledge on lifecycle, value chain and ecodesign altered the design guide

The collaboration included workshops with participation from FORCE Technology's experts in materials, electronics, lifetime testing, LCA, standards and legislation.

"We brought together several specialists at FORCE Technology during a workshop to get their perspectives and input on the tools. We went through the entire product lifecycle and value chain, providing input on different types of improvement potentials, such as material choices and product lifetime," explains Christine Bang Kragelund from FORCE Technology.

The collaboration resulted in concrete changes to Danfoss' design guide, which forms the basis for the RE:CIRC and DCI tools. Danfoss also received input on the data the guide is based on, for example regarding the use of scarce resources from an international perspective. In the DCI tool, priorities and weighting of different sustainability factors were adjusted.

We have received specific input and improvement suggestions from FORCE Technology. Now, we no longer feel alone in believing that we are making a significant effort. This also means we speak with greater weight and credibility to our customers.Lina Psarra / Circularity Lead, Danfoss

External insights enhance confidence and credibility in sustainability

The collaboration with FORCE Technology has assured Danfoss that the company has comprehensively addressed sustainability, ecodesign and circularity.

"We have received specific input and improvement suggestions from FORCE Technology. Now, we no longer feel alone in believing that we are making a significant effort. This also means we speak with greater weight and credibility to our customers," says Lina Psarra from Danfoss.

Evolutionary requirements for sustainable product development demand ongoing updates

After the 360-degree assessment of Danfoss' tools, the tools must now be implemented. Employees are being trained, and the tools will be made available to all company personnel. Practical experiences will then clarify where the tools can be further updated and adjusted.

However, the work does not stop here, as new regulatory requirements and knowledge will drive continuous improvements and annual updates to the tools.

"We must constantly consider new opportunities and adjust our practices. Ultimately, it's about Danfoss continually delivering both better and more sustainable products," concludes Lina Psarra.

Images: danfoss.com

Ecodesign

Read more about ecodesign here.

Related content

Case: Take-back and the EU’s Digital Product Passport

/Case

Conveyor belt manufacturer Ammeraal Beltech has reduced CO2 emissions and improved competitiveness.

In IoT startup Acembee, sustainability is no buzzword

/Case

Acembee had the sustainability of its IoT solution screened. This gave a more competitive product.

Sustainable product development

/Service

Sustainable product development – get help for a systematic product development process.

Sustainability screening – get help early

/Service

Get your mechanical, electromechanical or electronic product reviewed early in development.

Designing sustainable products

/Page

We need to rethink how we design products to make products last longer.

LCA – Assess environmental impact of your product

/Service

Document and communicate your product’s environmental impact with a complete life cycle assessment.