What you can do to ensure hygienic design

Hygienic considerations are still not fully integrated into the design process for food production plants. What can you do to ensure hygienic design?

Hygienic design has always been a forward-looking and a bit idealistic discipline with the grand goal of changing the design of equipment and facilities for easier cleaning. An easy-to-clean food factory provides a solid foundation for the maintenance of a sanitary environment with the possibility of producing safe, high-quality food.

In some connections, the idealistic nature of hygienic design can be an obstacle to implementation. Even when the need for design improvement is fully recognised, it takes decades to replace the existing equipment and plant base completely. The prevalence of hygienic design in practice is limited when redesign, replacement or change of equipment in process lines and facilities require major resources as well.

Hygienic design is a challenge

In Europe, hygienic design has grown as an independent discipline within food production equipment from the mid-1980s. Since 1989, the development has been supported by guidelines and certification from the European Hygienic Engineering and Design Group (EHEDG) as well as EU legislation, which was initially based on the Machinery Directive.

Today, the access to hygienically designed equipment is much easier, and the need for hygienic design is much more appreciated by producers of equipment as well as food. There are, however, still challenges despite the many good initiatives. There may be several reasons for that:

-

Hygienic design is regarded as an engineering discipline

Therefore, there is a risk that the hygienic design is disconnected from other activities associated with the overall process solution. At worst, this could mean that the fulfilment of user requirements may call for extensive examination and alteration of a delivery at an impractical time in the project.

-

Hygienic design is regarded as an absolute state for a design

The same solution may therefore be deemed adequate and appropriate for largely all applications. The result of this may be that a risk assessment of the specific application is not carried out. The design solution may thus be inappropriate, which may result in the choice of a solution that is too expensive or does not fulfil the need.

-

Existing equipment designs are neither phased out nor updated at the equipment producers to make them meet the current requirements

This may leave the buyers in a situation where they are not aware that they have bought a solution that does not meet present and future requirements with respect to, for example, sustainability, optimised cleaning and maintenance.

-

Users lack knowledge about the equipment they want to acquire

This may range from basic statutory requirements to the knowledge that the equipment supplier needs to be able to deliver the optimal solution. At worst, this results in the absence of a qualified dialogue, which may result in faults and defects in the process solution. At best, a supplier has been engaged that is able to drive the dialogue and adequately identify the need.

From component design to system thinking

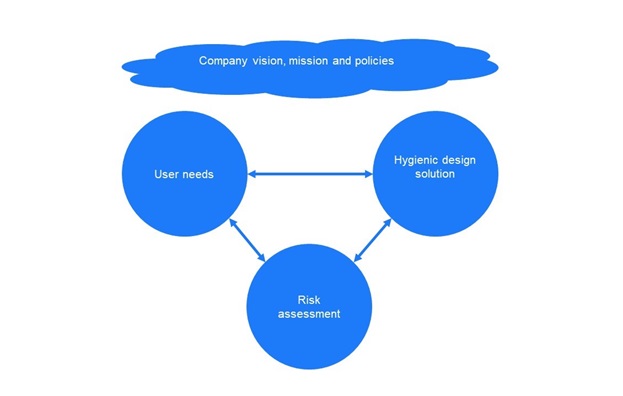

Traditionally, it is believed that hygienic design is more related to component design than to company policies and work processes. This is, however, an unnecessary and inexpedient limitation.

Setting an idealistic objective and application of the right hygienic principles yield good general cleanability and thus better food safety.

Fortunately, our way of looking at hygienic principles has changed over the years. This is reflected in the focus of new guidelines on the system, the factory, the cleaning process etc. At the same time, descriptions of appropriate work processes become increasingly extensive, for example with respect to integration of risk minimisation processes related to the achievement of good process hygiene.

The European legislation on food hygiene

The changes are supported by the European legislation on food hygiene (regulation 854/2004), which says that, in the future, food producers must draw up and maintain a food safety policy.

This means, among other things, that it is no longer possible to disclaim knowledge of how individual components interact to achieve the right food safety. You must also be able to formulate how you interact with equipment suppliers, cleaning players and others in a symbiosis in order to work according to principles that lead to the maintenance of adequate and necessary food safety.

User specification, hygienic design and risk assessment

The food producers may have to integrate the achievement of the right food safety into their general approach, but is that of any real importance for the equipment producers? Is that rather a disproportionate complication of the effort to achieve good hygienic design?

Global Food Safety Initiative (GFSI), which lays down the general requirements on which FSSC22000, BRC and IFS base their certification programmes for the food industry, does not think so.

By issuing a set of recommended requirements for system approaches regarding hygienic design and achievement of good food safety, the GFSI has already shown that the trend is in that direction. The requirements are that equipment producers must also have a food safety policy and be able to understand the food industry's risk assessment and risk minimisation.

Food safety must be integrated into policies and processes

The relevance of hygienic design is more obvious than ever before. However, it is clear that considerations in the future extend much further than component design as well as installation and maintenance of process lines.

This means that companies must integrate food safety and thus hygienic design principles into policies and processes. It will no longer be enough that things work. All parties involved must know more about how they work and what to do if a process deviates from the normal condition. This will of course involve changes for everyone who works with food production and supplies equipment and facilities for this.

However, it does not have to be difficult. A lot can be handled by structuring the work with process hygiene and equipment design with clear procedures and conducting internal training and updating of employees.

Management commitment important in the dialogue between producer and supplier

The achievement of good food safety will of course require more management commitment. Especially when the dialogue between food producer and equipment supplier in the future must zoom in on the degree of hygienic design that is needed and how much should be invested in this.

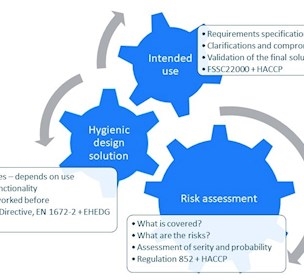

This process will optimally comprise the activities outlined in figure 1, and this may very well form the basis for the preparation of a systematic approach suitable for the individual company.

The companies that start out early and adjust the task to make it feasible and value-creating will have an advantage in the longer term. It is a good idea to start the process and create an overview of requirements and the extent of the task and then elaborate a plan. The implementation itself and the journey to embark on may take years if that is most expedient.

However, the message is clear: All players involved in the achievement and maintenance of good food safety will in the future be working on documenting that they have a system approach based on a form of food safety policy.

E-book: "Practical hygienic design"

Get help to ensure good process hygiene, practice and good hygienic design in food production and related industries.