Ensure hygiene and cleanliness in production processes

Checklists, systematics and processes can be the way to achieve the best result. The article presents a system for ensuring hygiene and cleanliness in the production processes in the design phase.

Obviously, one must not bend the regulatory requirements for food safety.

Nevertheless, the process of achieving a good hygienic process design and a good basis for hygienic production is subjective by its nature. It is subjective because food producers and machine manufacturers have to make choices and compromises in order to hit a level where set requirements are built into solutions that are affordable.

The elements of the iterative process

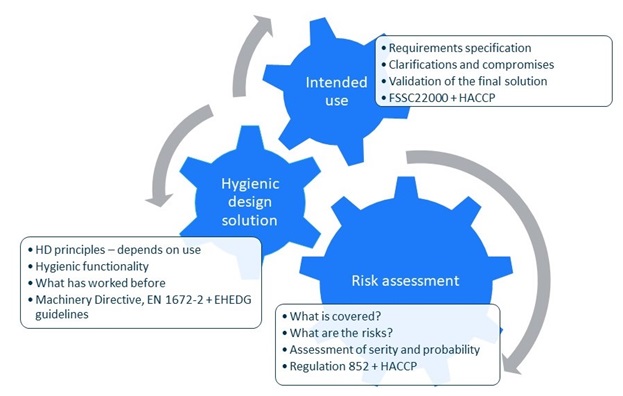

Therefore, it is crucial that the process of setting requirements (Intended use), finding solutions (Hygienic design solution) and making a relevant assessment of risks (Risk assessment analysis) to a certain extent is an iterative process.

As illustrated in the figure, the three activities impact one another, and it would be unwise to think that the process can unfold itself in a linear manner without feedback loops. The figure also explains which actions, questions and documents should be used in each of the activities.

To illustrate the use of the model, here is an imaginary example:

The food producer has a desire to produce a number of products in a new process and has already considered upon specification that it must be compatible with the existing systems. Based on a basic specification, a pre-screening is carried out and a few possible suppliers are selected for dialogue. Among other things, the dialogue is about whether standard solutions are sufficient or whether there is a need for new special design.

Already here, the project may have changed from what the food producer originally intended.

It is essential that the possible solutions are not only assessed in economic terms, but also assessed in detail to find the hygiene-critical components. In other words, where is the standard good enough, and where should greater considerations for hygiene be implemented. It involves ongoing risk assessment analysis and thus the activities impact one another.

The dialogue as an important tool

Many will say that there is nothing new here. It's true enough! The dilemma is not anything new.

What is new is to create a process where a production is reviewed in more detail with special attention to the hygiene-critical parts. This is based partly on the HACCP analysis that food producers must conduct in order to carry out the statutory self-checking and partly on how cleanliness is intended to be in practice.

It is thus about having a deeper dialogue between equipment suppliers and food producers.