Our place on standardisation committees builds important knowledge about electrical safety

The purpose of safety standards is to implement the requirements for safety in market requirements. This ensures the risk of damage to people, animals, environment, and property is kept down.

Electrical safety knowledge and experience need to grow

FORCE Technology carries out accredited electrical safety tests. To ensure we can do this correctly and professionally, we must continually build our knowledge and competencies. Taking part in standardisation work is one way of doing this.

Professional experts from our electrical safety group participate in different national standardisation committees:

S608 (IEC TC 108)

- Safety of electronic equipment within audio/video, information and communication technology

- IEC TC108 develops the IEC 62368 series, which has replaced EN 60950 and EN60065 in the EU.

S562 (IEC TC 62)

- S562 (IEC TC 62) develops the IEC 60601 series for medical electrical equipment.

IEC TC 66

- There is currently no national standardisation committee for IEC TC 66. Instead, we stay up to date by receiving material from the meetings in IEC TC 66.

- IEC TC 66 develops the IEC 61010 series, safety requirements for electrical equipment for measurement, control, and laboratory use.

At the forefront of standard development

Participating in standardisation committees puts us at the forefront of developing safety standards. Taking part in meetings, taking minutes, drafting standards and working papers, and getting input from the other members helps us stay up-to-date with the objectives, thoughts and plans for the individual standards. It gives us ample opportunity to predict what the particular standards require and arrange our test services accordingly. Our goal is always for test services to be ready when customers need them.

Positively influencing standard changes

The national committees are the national mouthpieces through which we can comment and propose standard changes. These fora give us a certain influence on upcoming standards, like when we voice our point of view to make sure Danish deviations are respected.

Interpreting requirements to help ensure correct production and test processes

The discussions during meetings and access regarding the written material lead to adjustments to the interpretation of the standards' individual requirements. The requirements are not always easy to interpret, challenging those using the standard to design a product. Incorrect standard interpretation can lead to a product not being approved or rejected altogether.

Professional network of experts within reach

Participation in standardisation work puts us into a network of other experts who we can call on to clarify areas where there is uncertainty or topics that need attention.

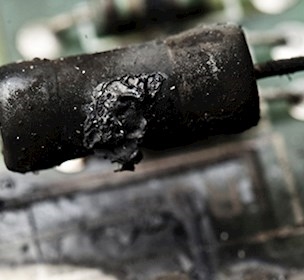

Exchange of experience minimises the risk of damages caused by electric and electronic equipment

Feedback from other test laboratories, manufacturers and authorities shows whether the standards can be used in practice. As a test laboratory, we test standards every day. Still, experience from manufacturers helps point out what might be hard to implement and or even meaningless to demand to fulfil the purpose of the standard, namely minimising the risk of damages caused by electric and electronic equipment. Participation in standardisation committees helps us get this necessary feedback.

For more information about electrical safety testing and our work on the standardisation committees, please contact Senior Consultant Poul Østergaard Madsen, tel. +45 43 25 12 79, or Senior Consultant Søren P. Petersen, tel. +45 43 25 15 19.