Uncertainty explained: How to calculate the laboratory CMC?

Do CMC values of the laboratories show the levels adequately with respect to the CMC as you will find in calibration certificates?

As a calibration facility, we often get questions on the performance of a meter, and whether it complies with guidelines like AGA and ISO. Next to this, we are often asked how the CMC value in the certificate meets the one published by the laboratory.

But what is CMC, and how does it involve the uncertainty of the laboratories? Let us try to explain.

What is a CMC value?

Calibration and Measurement Capability (CMC) is a value, that expresses how well a laboratory can measure. CMC is not necessarily a fixed value. It can be given as a precautionary range depending on flow and calibration pressure. The uncertainty often increases when flow and pressure are lowered.

Most calibration laboratories in the world have their CMC values published by their National Accreditation Body. The National Metrology Institutes (NMI) also have their CMC values published in the BIPM´s key comparison database (KCDB).

However, do these show the levels adequately with respect to the CMC as you will find in a calibration certificate?

E-guide: Understand calibration certificates

Factors to be considered when calculating calibration uncertainty

First of all, we need to understand the calculation of uncertainties. When a gas meter is calibrated, we find a CMC uncertainty (UCMC) and a calibration uncertainty (Utot) in the certificate. From this, the calibration uncertainty (Utot) will always be higher or equal to the CMC uncertainty (UCMC).

Many uncertainty contributions are relevant when calculating the (UCMC). This depends, among other things, on the principle of the calibration facility, the traceability chain, correlating uncertainty and the internal maintenance program and set intervals for quality equipment re-calibration.

Some typical uncertainty contributions are:

- The calibration of the working standards and the long-term stability of them are usually the major contributors to the uncertainty.

- Line pack may have some influence on large volume systems where pressure and temperature are not stable during calibration, but also pressure measurements, temperature measurements, determination of the compressibility, pulse and/or mA collection may have an influence.

- Uncertainty contributions arising from interpolation between calibrated flow points and calibration pressure must be included.

- Last - but absolute not insignificant - the uncertainty of how well the error can be repeated, where the device under test (DUT) comes into the calculations of the calibration uncertainty (Utot).

Next up - how to calculate these values since there are several ways to calculate the (±Utot)?

Read more: Uncertainty explained - Class half meters

Calculation of the reported calibration repeatability

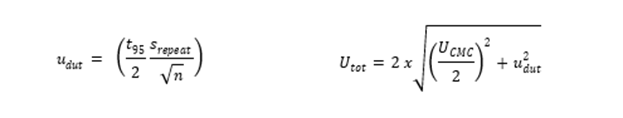

The reported repeatability (udut) is calculated in accordance with "WGFF Guidelines for CMC Uncertainty and Calibration Report Uncertainty" by using 95% confidence level t-value for n-1 (number of runs - 1) degrees of freedom, divided by and assuming k95=2:

When Srepeat is zero or close to zero, the calibration uncertainty is equal to the CMC uncertainty. However, this is often not the case. We see that the Srepeat can be quite high, caused by the repeatability of the meter.

Note that, in case of poor repeatability it can be wise to run additional repeats. The Srepeat should in theory not lower with more repeats, but it can sometimes be advised to rerun a calibration point to get a lower repeatability.

As can be seen in the formula for udut, with more repeats, n becomes higher, and t95 becomes lower, and thus the repeatability udut will automatically be lower. The reason for this is that the average error can be determined more accurately on the basis of several repeats.

Please note that the influence of the repeatability from the calibration facility can have a smaller influence since this is captured in the CMC of the laboratory.

Why is CMC important?

So, the Ucmc plays an important role in the total uncertainty.

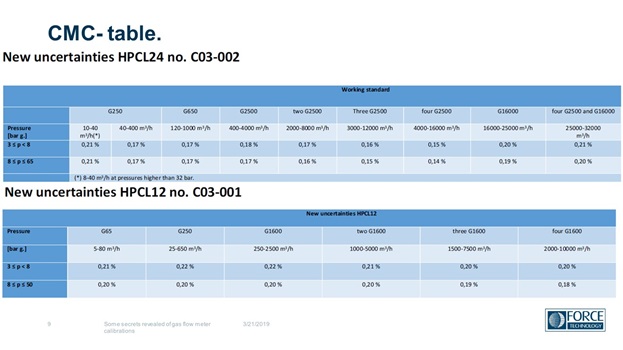

It should be noted, again, that the CMC is not a constant value. Published on the certificate are the best CMC possible, not the CMC values throughout the calibration capabilities of the laboratory. The CMC value varies over pressure and flow, and numbers of Working Standards in the calibration, as shown in a CMC table of a laboratory (Here FORCE Technology).

The calibration uncertainty (±Utot) can only be determined after the calibration is completed. It is not possible to order a calibration where the calibration uncertainty must be less than e.g. 0.2%, since this depends of the meter performance.

However, we often see that the uncertainty contribution of the meter is very small, and the calibration uncertainty is only 0.01-0.02% higher than the CMC value of the laboratory.

Want to know more about uncertainty and CMC?

- You can learn more about CMC by reading the next article in the series:Uncertainty explained - Understanding an uncertainty budget

-

Contact us for a discussion.

- Sign up to receive news and articles about gas flow calibration

- You can also learn more about Calibration here.

Related content

E-guide: Understand calibration certificates

/Article

Uncertainty explained: Class half meters

/Article

Most laboratories in the world don’t have uncertainty levels adequately low to perform accredited calibrations of a class half meter. How does this affect the gas metering industry?

5 arguments for re-calibration of gas meters

/Article

Why perform re-calibration of gas meters? 5 gas industry professionals share their opinion.