As NOVENCO joins the circular economy, IoT and big data pave the way

IoT technology has granted NOVENCO Building & Industry access to big data. As a result, the company has gained knowledge, saved resources, and significantly extended their products' lifetimes.

The circular economy and data-driven product optimisation go hand in hand. That much became obvious to NOVENCO Building & Industry, a manufacturer of ventilation equipment, after seeing the results of their collaboration with FORCE Technology.

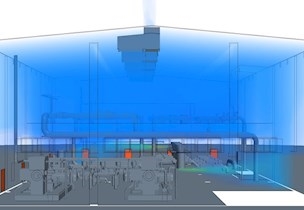

Implementing IoT technologies in selected products has enabled the company to collect comprehensive product data. This data can be used for smart ventilation management, so the company's ventilation units run optimally, last much longer, and use as little energy as possible. All in all, the result is significant savings for customers and a sustainable competitive advantage for NOVENCO.

A green, digital future for a ventilation company

Located in Næstved, NOVENCO Building & Industry is part of SCHAKO Group, which is based in Switzerland. The company produces ventilation equipment for facilities like data centres and multi-storey car parks. Optimal energy usage and sustainability are two of the company's core values.

NOVENCO wanted to know more about how its customers use its ventilation units. The company suspected that many of its units were overspecified, resulting in excessive energy consumption — but how could it be certain?

The energy required to operate an industrial ventilation unit over its lifetime typically costs 5 to 50 times as much as the unit itself. To offer its customers savings and better understand how to optimise energy usage, NOVENCO wished to collect data from units in operation. The company also wished to improve its image in terms of circular economics.

"The products we offer typically lack management and control features, and that had been bothering us for a while," says Peter Holt, technical director at NOVENCO Building & Industry. "That issue, combined with the increased level of digitalisation in the world, led us to think about ways we could make our ventilation units smarter and less resource-intensive."

Big data holds the keys to optimal ventilation

Ahead of a circular economics workshop, NOVENCO contacted FORCE Technology, which quickly proved to be a valuable source of technical input. With financial assistance from MUDP — Denmark's national eco-innovation programme — and with FORCE Technology as a subcontractor, the company launched a project entitled IoT Data-Driven Resource Optimisation.

The project used FORCE Technology's existing wind turbine monitoring solutions as a starting point. These solutions use sensors to collect vast quantities of data, often referred to as "big data," although the task in this project is on a smaller scale. Subsequent analyses and calculations using the collected data left NOVENCO with a treasure trove of information about its products.

"Working with big data is no walk in the park. Before doing anything else, we had to figure out what we could do with these huge volumes of data," Holt explains. Use cases are one possibility: "Ventilation units are always designed with a worst-case scenario in mind: For example, they need to be able to clear the air of smoke in the event of a fire, but fires are rare in practice. If we instead consider a variety of use cases for ventilation units, each of our customers can choose the best unit for their particular application. This also allows us to calculate a realistic lifetime for each unit. In terms of energy consumption, this is a totally different, more sustainable perspective," says Holt.

Significant lifetime extensions come with major resource savings

NOVENCO Building & Industry had a theory that they could extend their ventilation units' lifetimes if the units did not constantly run at full capacity — a theory that proved to be true. From experience, the company already knew that the bearings are the weakest link in a ventilation unit.

"Lifetime models developed based on IoT data and motor vendor data showed that we could extend the lifetime of a motor by five to ten years if we simply considered a more realistic load for a given unit," says Holt. "We expanded our model to also include the frequency changer, and we determined that we could extend the lifetime of a unit from five years to more than 20. The resource savings that come from that are incredible," Holt adds.

To make these lifetime extensions reality, NOVENCO first needed to know how its ventilation units operated. Its customers themselves rarely have much information to offer in that regard, so this is where IoT comes into play. FORCE Technology has continually contributed to the project, from suggesting sensor-based monitoring in the project's early phases to writing software for the current phase.

"We can use IoT-based data collection to offer a remaining lifetime calculator, enabling customers to use each unit for the entirety of its useful life. This drastically decreases our products' environmental impact, and it saves our customers large sums of money. Not only that, but we can also take a more proactive approach to our service business, since we can predict when a unit is likely to need service," explains Christian Agular Knudsen, a fluid mechanics development engineer.

Life cycle assessment provides tangible documentation

It's one thing for NOVENCO Building & Industry to collect data on resource savings, but documenting them for their customers and the world at large is another thing entirely. For that reason, FORCE Technology has helped NOVENCO to document just how sustainable its ventilation units are by developing a life cycle assessment (LCA for short). An LCA offers an overview of the impact a product has on nature and the environment throughout its lifetime. An LCA can also serve as a starting point for preparing an environmental product declaration, which documents the impact of an individual product on the environment.

"On top of that, a recycling analysis showed that 98% of the material in our units is recyclable, since steel and aluminium can both be melted down. We aren't stopping there, though — we're going to continue to develop algorithms for optimising our products, improving them, and making them even greener," Knudsen says.

A greater focus on sustainability and environmental certification

Sustainability has become critical in the construction industry, which is one of NOVENCO's most important customer segments. NOVENCO hopes to offer IoT-based ventilation monitoring as an energy optimisation tool for buildings. Specifically, the company plans to develop an interface for building management systems.

Data centres are a primary consumer profile in the ventilation industry, with some centres having as many as 1200 units installed. For them, units with significantly extended lifetimes have incredible potential in terms of finances and resources.

"Some of our data centre customers already require LCAs, and more and more contractors are now also requesting EPDs. Since there still aren't many actors in the industry offering LCAs, we're already ahead of the competition. We're able to present ourselves as a qualified green partner," Holt explains.

NOVENCO has earned a variety of sustainability certifications that it is already using in its marketing, including certifications from LEED, DGNB, and Breeam. Additionally, the company's ZerAx unit is Greenpro-certified in India.

Reaching new heights and gaining new perspectives from a strong partner

Now, NOVENCO is ready to implement the results of the MUDP project in its strategy for the future, paving the way for even more green, resource-saving initiatives.

NOVENCO has thoroughly enjoyed working with an experienced partner on their MUDP project, and Holt has a clear message to share with other small businesses: "For a project of this scale, a partner is an absolute necessity. That's how we were able to just focus on the technical side of things," he explains. "We could never have imagined just what we were getting into and what kind of journey it would lead us on.”

“FORCE Technology put their knowledge, facilities, and resources at our fingertips as we drew on their high level of expertise. It's so valuable for us to get that outside perspective on things. We've taken a huge step towards a green transformation and sustainability, and we've gained such an incredible amount of knowledge. In the end, it all benefits our customers," concludes Holt, the technical director at NOVENCO Building & Industry.