Obtain accredited testing as documentation for the photobiological safety of your products

Are you aware of the requirements for documenting photobiological safety when you plan to sell and market your products with various light sources such as visible light, IR, and UV?

When producing and selling light sources like light fixtures, lamps, projectors, and other forms of artificial lighting, you must document that the light source is safe for human use before it can be sold. Light sources can pose dangers to both eyes and skin, potentially causing conditions such as retinal burns or inducing photochemical damage.

Request a customised photobiological safety test and design advice

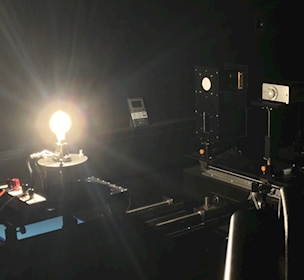

You can arrange for a customised photobiological safety test, specifically tailored to your unique needs and product types. This includes versatile testing arrangements capable of handling a range of light sources, from LEDs to complex lamp systems.

You are welcome to visit our laboratory and facilities, and you may also observe the photobiological testing if necessary.

Beyond the testing itself, you can receive assistance in analysing the results, along with advice on your design and the essential support needed to implement changes should your product fail to meet the requirements.

Request a quote for a photobiological safety test

Accelerate your product development phase, ensuring timely approval and market launch.

Our photobiological safety tests help your products meet international safety standards efficiently. With our accredited tests, we accurately measure optical radiation emissions, safeguarding users and providing the necessary documentation for global market access.

When preparing to sell and market your light sources, you should consider the following:

The type of light is crucial for ensuring photobiological safety

Lighting technology has seen significant advancements. Whereas it was once dominated by incandescent bulbs and fluorescent tubes, LED bulbs are now extensively used across various sectors.

At the same time, UV lighting is being employed more widely in a diverse array of applications and sectors, including water treatment, air purification, surface disinfection, and medical treatments.

This shift in technology introduces new challenges, particularly in terms of photobiological safety.

Different types of light and their associated risks

Blue light

Blue light emitted from powerful sources such as LED chips is particularly detrimental to the eyes, known as Blue-Light Hazard. It can potentially trigger a photochemical reaction, thereby damaging the retina. Consequently, it necessitates a thorough risk assessment.

Infrared light (IR)

Known for emitting thermal energy, IR light is utilised in various applications, from surveillance cameras to signal transmission. It can lead to eye damage if exposure is prolonged. A notable risk associated with IR light is its inability to trigger the eye's natural protective mechanisms due to its invisibility, hence not eliciting a visual response.

Ultraviolet light (UV)

Employed across several industries such as pharmaceuticals, biotechnology, and the food industry, as well as in the entertainment sector. UV-A and UV-B are widely used for medical and commercial purposes such as promoting plant growth, disinfection, and material testing, including use in tanning beds. UV-C's potency makes it ideal for microbial control and sterilisation in both the healthcare and food sectors. Nevertheless, UV radiation poses dangers to both the skin and eyes, thereby necessitating dosage limitations. This implies that the more intense the radiation, the shorter the duration of exposure should be.Legislation regarding photobiological safety

It is a requirement from the EU that light sources, as well as devices utilising these, undergo a photobiological risk assessment per DS/EN 62471:2008 to ensure both product safety and personal safety.

To ensure your light sources can be safely marketed, securing an accredited report from a recognised third party is vital. This document is essential for obtaining approvals such as CE marking, which demands compliance with the EN 62471:2008 standard. This standard is also required to fulfil the criteria set by the EU’s CCA and ENEC schemes.

If you seek a thorough understanding of legislative requirements and their impact on your business across various markets, it is crucial to collaborate with expert’s adept at navigating these complex standards to ensure all products are in full compliance.

Please do not hesitate to contact us if you need assistance testing the photobiological safety of your products.

Related content

Photobiological safety – What and why?

/Article

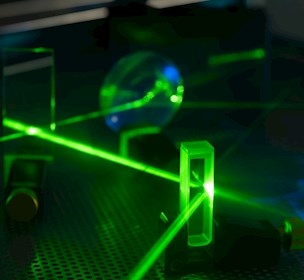

Photonics, light, and optics laboratories

/Facility

Accredited testing of e.g. sensors, light sources, lighting products and retroreflective materials.

Accredited tests of retroreflective materials

/Service

Verify compliance of retroreflective materials and sheeting according to relevant standards.

Accredited light measurement of light sources

/Service

Get tested and verified if your light sources and lighting systems meet requirements and standards.