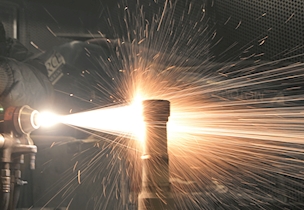

Facilities for thermal spraying and metallisation of surfaces

Please take advantage of our thermal spraying and metallisation facilities when you need new surfaces on your components to perform repairs, prevent corrosion or add wear resistance.

The many possibilities of thermal spraying and metallisation

In thermal spraying and metallisation, you have a solution that can be adapted to a wide range of parts – from small precision parts to large and complex components.

This advanced process, which includes arc and plasma spraying, makes it possible to apply wear- and corrosion-resistant coatings to modify the functional properties of surfaces. This way, you can extend the lifetimes of your critical components.

Thermal spraying can also be used to salvage a part with too much material shaved off.

You can achieve the optimal solution with these benefits and more:

- Applicable to both small and large items

Whether working with small or very large parts, thermal spraying and metallisation are flexible solutions. The process can be adapted to suit everything from small parts to significant, heavy industrial compo-nents, giving you the same high precision and quality regardless of part size. The facility can handle items ranging from ø15 mm to 1.5 x 1.5 m in size.

- Manual or robotised process

You can choose between manual and robotic thermal spraying and metallisation, whichever suits your project best. The manual process provides flexibility to customise work for unique or complex items, while robotic systems ensure consistency and fast processing for larger batch jobs.

- Mobile thermal spraying and on-site metallisation – we come to you

If your items are too large to be transported, mobile equipment allows you to have thermal spraying at your premises, eliminating the need for disassembly and transportation. The mobile solution makes it possible to process large or hard-to-reach components efficiently and accurately at your location.

Metallurgical and mechanical testing knowledge at your disposal

Please use our extensive metallurgical understanding of materials and their properties to help you choose the optimal surface for your parts and components.

Once parts have been thermally sprayed or metallised, you can have them subjected to various tests, such as:

Contact us if you need further information or have any components you would like thermally sprayed or metallised.