AVK takes the lead in testing equipment for the Power-to-X transition

A specially developed hydrogen valve test has given AVK International A/S the opportunity to conquer new markets and create a greener image of its brand.

AVK leads the way in Power-to-X and the green transition

With the advent of power-to-X technologies, hydrogen is becoming a major source of energy. Mixing hydrogen into natural gas and transporting it through the existing natural gas network seems like an obvious option, but is it technically feasible?

"We want to be at the forefront of developments in transporting hydrogen through the natural gas network," explains Simon Slumstrup, a product manager at AVK International A/S. "That's why we want to know if our valves can withstand long-term exposure to hydrogen."

One of the challenges with hydrogen is that it can diffuse into metals over time, such as the metal components of a valve. If this happens, it can cause the metal to become brittle and prone to developing cracks. Leaks and hydrogen-tightness are also focal points, given the small size of hydrogen molecules. In the worst-case scenario, an explosion could occur within a gas pipeline or in a Power-to-X system.

Specially developed tests simulate long-term impact of hydrogen

Since Power-to-X technologies are not yet mature, there are no standards in this area, and it is difficult for manufacturers to determine how to have their products tested. The majority looks towards ASME B31.12 on Hydrogen Piping and Pipelines, but specific guidance on how to test components in hydrogen is absent.

"We needed to have a test developed in order to determine whether our valves could withstand long-term exposure to hydrogen. We can't conduct these kinds of tests ourselves because they require extensive safety measures. Hydrogen is extremely flammable, and our valves have to be tested under pressure," says Slumstrup.

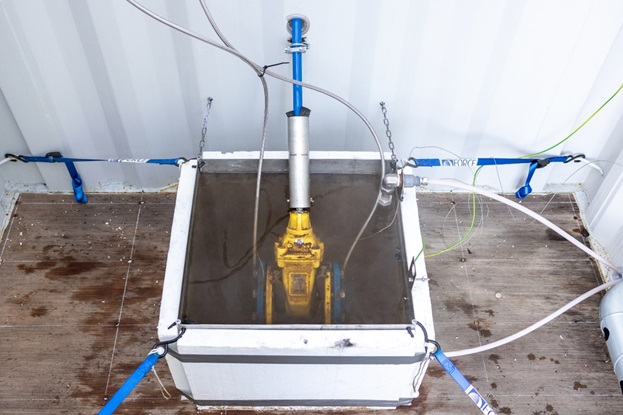

AVK and FORCE Technology collaborated to develop specialised, comprehensive tests based on FORCE Technology's knowledge of the field. These specialised tests fulfilled AVK's needs for a way to test the long-term impact of hydrogen on its valves under simulated operating conditions.

Two tests were developed: a functional test, which simulates a valve's entire lifetime; and a burst test, which exposes a valve to increasingly high (and eventually unrealistic) pressures until it fails. A tested valve can then be compared to a control valve that underwent a lifetime test in an inert gas to determine whether the hydrogen damaged the tested valve.

The facilities used for the test are part of The Hydrogen Technology Testing Centre, funded by GLDK, which is a collaboration with Evidas Testcenter.

Conquering new markets with peace of mind and a greener image

Preliminary valve test results have shown that AVK's valves can, in fact, be used to transport hydrogen through the natural gas network.

"Having this certainty as to what our products are capable of gives us peace of mind. That's usually why manufacturers like us contact people like you to have products tested.

In the long term, this enables us to create a greener image of our brand. It also opens up new opportunities for us, not only in existing markets, but also in new markets without a history of using natural gas," Slumstrup explains.

The need to develop power-to-X tests and standards

AVK is the first company in Denmark to have tests of this kind developed. The company wishes to maintain its lead by continuing to test its valves and contributing to the development of tests for power-to-X technologies and in other areas.For us as manufacturers, helping to establish a framework and contribute to the development of standards in this area is a great advantage. Manufacturer involvement is important so we don't end up with unrealistic requirements that nobody will ever live up to in practiceSimon Slumstrup, Product Manager / AVK International A/S

Related content

The hydrogen technology testing centre

/Facility

Safe hydrogen transport

/Article

Safe hydrogen transport is an “enabler” for Power-to-X.

Standardised tests and special procedures - materials

/Service

Get documentation that your product complies with material requirements and specifications

HPHT testing in realistic environments

/Facility

Test facilities for testing of metals, coatings, polymers, composites and assemblies/ components.