Tanker shipping company tests biofuel on its journey to lower emissions

Uni-Tankers has declared a goal to reduce its emissions and its climate impact. One way to accomplish this is by using 30% biofuel in its ships. The effect has now been measured and documented.

Since 2014, Uni-Tankers, a Danish tanker shipping company, has been working diligently to reduce its impact on the climate and the emission of harmful substances. Today, this issue is at the top of the company's strategic agenda.

Furthermore, the shipping industry has become increasingly subject to regulation. The International Maritime Organisation (IMO) has set targets for carbon-neutral fuel usage to be at 5-10% by 2030, and for zero emissions by 2050.

Fuel as a critical challenge

Uni-Tankers knows that for the company to reduce harmful emissions and its impact on the climate, focusing on fuels is key.

"96% of our emissions come from our fleet of 32 ships, so that's where we have an opportunity to make a big difference. Basically, we need to either use less fuel or greener fuel. On top of that, our ships need to be designed sustainably, of course," says Lisa Clement Jensen, Head of Strategy at Uni-Tankers.

There are two basic pollution issues associated with ship fuel: CO2, which primarily comes from the production of the fuel itself, and the emission of harmful substances during combustion: namely, particulate matter, NOx, and carbon monoxide.

30% biodiesel fuel tested

To make its fuels greener, Uni-Tankers decided to have FORCE Technology test something known as B30 fuel. The name "B30" indicates that the fuel contains 30% biodiesel. The remainder is the common fossil fuel called LSMGO (Low Sulphur Marine Gas Oil).

One of the reasons Uni-Tankers decided to test a B30 mixture in its ships is because the IMO considers B30 to be equivalent to fossil fuel. The relatively low biofuel content means that ships can begin running on B30 without the need for their motors to undergo recertification by the IMO. This is comparable to the situation with our petrol-powered cars, which can also run on 10% bioethanol.

Jensen says that striking a balance between sustainability, fuel consumption, and expenses was another important factor in their decision. "Having a fuel that's 30% more sustainable wouldn't do any good if our fuel consumption also rose by 30% or more."

Significant decreases in key climate parameters

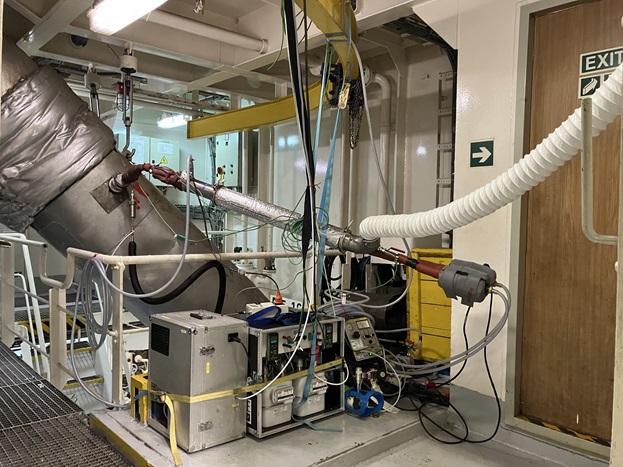

The B30 fuel test was conducted over two days on the M/T Alsia Swan, one of Uni-Tankers' chemical tankers. FORCE Technology joined the ship in Antwerp before it sailed through the English Channel. During the journey, specialists conducted accredited testing and measurement under four load conditions to measure the reliability and performance of the fuel mixture.

The results showed that switching from traditional LSMGO fuel to the B30 mixture can reduce particulate emissions by up to 42%. While no significant change in NOx emissions was observed, carbon monoxide emissions fell by 18%. Based on these tests, Uni-Tankers expects to be able to reduce the climate impact of its CO2 emissions by up to 30% relative to fuel consumption, if the company switches all of its ships over to the B30 fuel used in testing. This is based on the biogenically derived proportion of the B30 fuel.

Meeting strategic sustainability goals while benefiting customers

"These tests have taught us some valuable lessons about using biodiesel in our ships. It's an important step towards reducing our impact on the climate, and that's at the top of our strategic agenda," Jensen says.

Uni-Tankers also notes that being able to demonstrate the positive impact on health and the climate of using biofuel to transport goods is a major asset with respect to their customers.

"This isn't our first time working with FORCE Technology. The whole process was frictionless, and the coordination was great from start to finish. We chose FORCE Technology because it's an internationally recognised GTS institute capable of making accredited measurements," explains Kristian Larsen, Technical Director at Uni-Tankers.

These tests have taught us some valuable lessons about using biodiesel in our ships. It's an important step towards reducing our impact on the climate, and that's at the top of our strategic agenda.Lisa Clement Jensen / Head of Strategy, Uni-Tankers

The more biodiesel, the better – right?

Having learned more about the potential that B30 fuel has to offer, Uni-Tankers is taking the next step in testing. The company is currently in talks with FORCE Technology to test another type of fuel: a B15 mixture, which contains 15% biodiesel.

"Testing another fuel with a lower proportion of biodiesel might sound like a waste of time and effort at this point. But as it turns out, laboratory studies show that fuel consumption is 10% lower with B15 because it has greater oxygen content, which lubricates the motor. We want to get some numbers on this so we can see if B15 is really the "sweet spot" for biodiesel mixtures," Larsen says.

Towards zero-emissions shipping

In the context of the zero-emissions shipping target for 2050, fuels containing 15% or 30% biodiesel can be considered part of a transitional stage.

The goal is to operate a fleet that runs entirely on alternative fuels, such as methanol. Doing so requires new motors, major investments and more mature technology.

In that sense, the journey towards greener shipping has only just begun, and that journey is all about learning and testing. That said, Uni-Tankers has set a clear course and got off to a strong start.

Related content

What is carbon capture, and how does it work?

/Article

Emissions in the green transition

/Project

Cooperation ensures that no new environmental problems derive from new green fuels.

Airborne emissions, incl. odour and micropollutants

/Service

Emission measurements ensure compliance with regulatory requirements for measuring.

The Air Testing Laboratory

/Facility

The industry’s access to test of air emissions, air quality, indoor climate, and working environment