Activities in the Digital Factory Acceleration programme

How does the 'Digital Factory Acceleration' programme help your company succeed in digital innovation? What are the steps to go through? How long do they take?

Why the 'Digital Factory Acceleration' programme?

Digital innovation offers the chance to improve the performance of production and supply chain operations, increasing profit margins as well as competitive advantage.

The core needs for succeeding in a digital innovation journey are:

- Identifying the right projects: each company has its own requirements, needs and goals

- Quantifying the potentials behind digital innovation projects: you need numbers to be able to formulate a business case

- Having access to the right competences: the execution of digital innovation projects often requires competences in several domains – often new.

Production companies often struggle in successfully addressing these needs and, consequently, in their digital innovation journey.

The 'Digital Factory Acceleration' programme is built on a well-defined sequence of steps (described below) to make sure companies will succeed in covering these needs.

What are the 'Digital Factory Acceleration' steps?

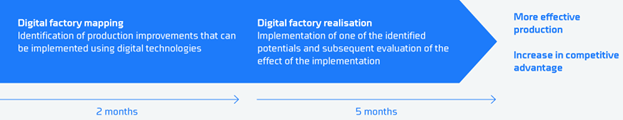

Each participating company will go through a 'Digital Factory Mapping' phase - where digital innovation opportunities will be identified and their potentials quantified - and a 'Digital Factory Realisation' phase – where the best opportunity will be captured through the implementation of an actual solution.

During the 'Digital Factory Mapping' phase, your company will go through a digital factory mapping, a state-of-the-art analytic approach based on a synergy between the lean toolbox and the digital maturity concept. The process will cover a time span of two months and includes:

During the 'digital factory realisation' phase, your company will be supported in the implementation of the most relevant solution in order to capture the identified improvement opportunities and the related potentials. The process will cover a timespan of circa five months (depending on the project) and includes:

If you want to learn more about the 'Digital factory mapping', don’t hesitate to contact us.

Related content

Unilite continues collaboration within DFA project

/Page

Read more about the company's plans to improve production.

Knowledge-sharing initiatives throughout fall 2023

/Page

Read more about the knowledge-sharing activities

Continued collaboration with Baden-Jensen

/Page

A one-and-a-half-month sprint project results in an overview of core challenges and their solutions.

Unilite joins DFA programme

/Page

Unilite seeks guidance and support in solving the product configuration problem

Brandt A/S joins Digital Factory Acceleration programme

/Page

Leading industrial coating company joins DFA programme to enhance growth.

Valsemøllen begins DFR phase of DFA programme

/Page

Valsemøllen has identified three main focus areas for Digital Factory Realisation phase.