Paving the way into Industry 4.0 with digitalisation in manufacturing

The ability to digitise manufacturing operations is key to enable businesses to succeed in international markets with competitive turnaround times, prices, and quality. FORCE Technology wishes to accelerate this digital transformation to bolster the competitiveness of Danish manufacturing businesses.

Digitalisation: an essential differentiator

Many manufacturing businesses have great potential for digitalisation, but this potential often goes unrealised due to a lack of resources, expertise, or the right business case. However, the ability to digitise manufacturing and production processes can be key to the success of a manufacturing company in highly competitive global markets.

Turbo-charging digitalisation for SMEs

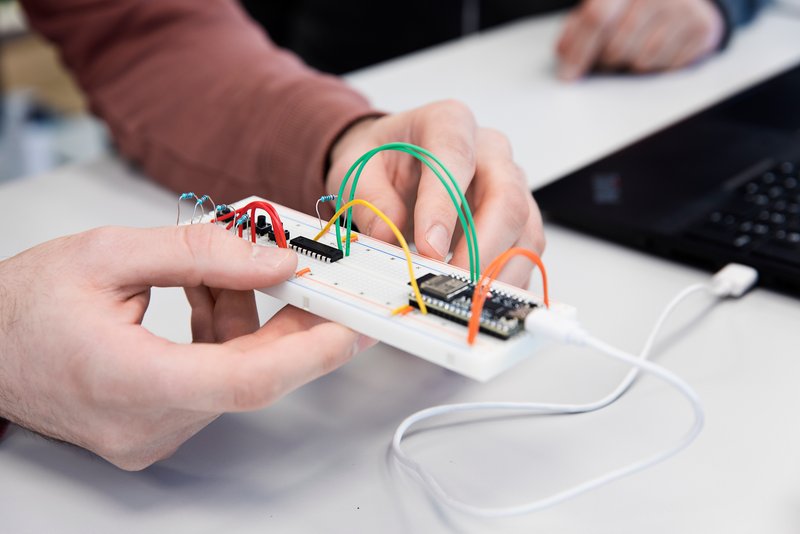

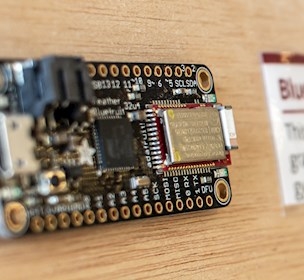

This is why we at FORCE Technology are working to turbo-charge the Industry 4.0 transformation—particularly when it comes to Danish SMEs. At the heart of Industry 4.0 is the digitalisation of existing physical devices in manufacturing, creating entirely new opportunities for integration, automation, and control in production and value chains.By pairing years of expertise and experience in materials, engineering, structural analysis, inspection, safety, calibration, testing and measurement with consultancy on digital technologies, such as advanced sensor technology, IoT, digital twins and machine learning, we aim to improve the production and value chains in Danish manufacturing companies.

We can help analyse your digitalisation potential and help establish a predictive maintenance solution

To accelerate the digital transformation of Danish companies and help them on their way to Industry 4.0, we are working on:

Opportunities for digitalisation

Identifying opportunities for digitalisation in manufacturing companies as part of the Digital factory project.

Maintenance

Supporting the selection of the right maintenance strategies in manufacturing operations, whether predictive or reactive.

Solutions

Developing the best, most innovative digital solutions in our centres and hubs.Cases

IoT solution saves tonnes of fish and a lot of money

/Case

ReMoni's sensor system detects error signals in fish deboning machines.

Automation saves manufacturing costs

/Case

BSV Krantilbehør reduces manufacturing costs on core products by more than 10%.

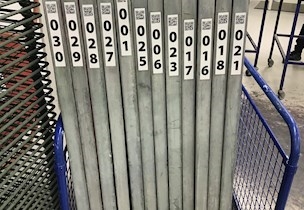

Supply chain optimisation whith IoT solution

/Case

At NS System, IoT reduces downtime as well as the trouble of equipment hunting.

Learn more about digitalisation of productions

Meet an expert in datadriven maintenance

/Article

Get practical tips on improving cost-efficiency, safety, asset lifetime and quality.

Nordic IoT Centre

/Project

Nordic IoT Centre helps companies realise the value of IoT.

Advanced real-time monitoring in supply chains

/Article

How will supply chains be monitored and overseen in the future?