Drone inspection of power and hydro power plants

Power plants consists of many different buildings, equipment and pipe systems that all need to function properly for the plant to be efficient. Drone inspection is a safe and fast way to overview the state of your plant.

An increasing number of companies today are using drone technology for visual inspection, as it is a cost-conscious and effective way to inspect at heights and inaccessible areas.

The use of drones for inspection of power and hydro power plants offer advantages such as:

- quick overview and evaluation of the condition

- sharp and detailed photographs of defects

- high quality images and video

- preventive maintenance planning and optimised production

- access to hard to reach areas

- reduced downtime

- high level of personnel safety.

High-flying inspection of chimneys

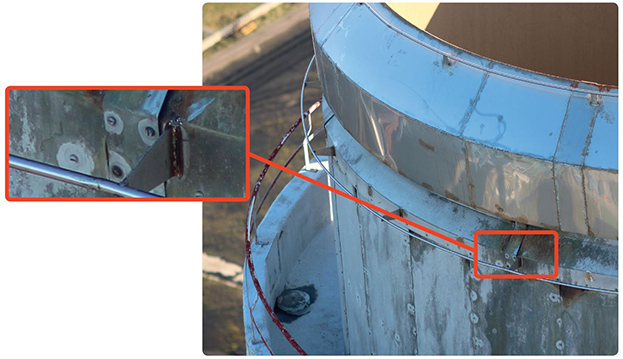

Thunderstorms can leave damages from lightning strikes in the concrete, to the lightning conductor or to the chimney structure itself, exposing the reinforcing steel. Drone inspection enables a quick and cost-conscious inspection of chimneys revealing details of damages like corrosion areas and cracks in the concrete, enabling immediate action.

Inspection of the general condition and of specific chimney accessories can be performed both as a screening of the surface or by focusing on details. Inspection by drone is fast and gives you visual data, which is useful in the maintenance and repair work.

Normally drones are restricted to flying at an altitude of 100 meters. FORCE Technology is authorised to carry out inspections higher than 100 meters. Therefore, inspection of a 225-meter chimney and tall masts are not a problem.

Inspection of confined spaces - boilers and storage tanks

Drone inspection of boilers, fuel storage tanks and confined spaces at power plants, refineries and other industrial plants is becoming commonplace. Here visual inspection using a drone is advantageous as it often is too expensive or time consuming to set up scaffolding, or too hazardous for physical inspection.

However, there are considerable challenges when using drones in confined spaces, these include lack of proper lighting, colour nuances, radio signal reflection and propeller turbulence. We meet these challenges by using powerful LED lamps, thus ensuring good picture quality with true, natural colours, as well as using specialised equipment and experienced pilots who can predict areas with high risk of turbulence.

The quick deployment time and ability to either screen a whole area or quickly get details of specific sections make drone inspection ideal for time critical inspection. The data provided by the drone inspection will significantly improve your maintenance planning, as it can be used to reduce maintenance related downtime and costs.

Building and rooftop inspection

A proactive inspection of buildings, rooftops and gutters or documentation of material damages after storm or other accidents is easy, safe and fast with our drone inspection solution.

Still images and video recordings are useful when inspecting rooftops, facilitating the detection of faults or defects. For detection of heat related faults or defects inspection a thermographic camera is attached, which quickly can pin out potential leaks.

Leak inspection of district heating piping

The FORCE Technology drone inspection solution can perform a thermographic inspection of underground district heating pipelines. Equipped with a thermographic camera the drone can locate areas in the piping likely to fail and cause leakage, so the owner can repair it.

With drone inspection, it is possible to cover larger grounds faster compared to traditional inspection methods for district heating pipelines. Thus, eventual leaks will be located faster so energy losses can be avoided and huge savings achieved.

Only experts ought to analyse data

During the aerial inspection, a FORCE Technology pilot operates the drone. During the flight, our certified NDT personnel usually operate the camera, record video and direct the pilot to the points of special interest and views of different angles of the construction.

Under normal circumstances, the drone inspection itself is quickly finished. The heavy workload lies in the analysis of the collected data, and the pictures taken from the drones. It is essential here to enlist relevant experts in analysis to obtain the full value from a drone inspection. Someone lacking the necessary qualified experience may overlook a critical defect or fault, possibly with fatal consequences.

An inspection report is produced, based on the analysis of the data, and is usually divided into categories of red, yellow and green priority according to the seriousness of the damage. This report can if needed include a service plan, with recommendations to cost-effective improvements.

At FORCE Technology, we only use drones when we conclude that it is the optimal solution. Based on our extensive experience with and knowledge of all types of inspections, we always offer the best solution, tailored made for the job – with or without a drone.