Third party inspection of wind turbine foundations and towers

Make sure that your wind turbine foundations and towers are manufactured according to the current standards and in accordance with your requirements.

Quality assurance reduces costly repair

Quality assurance is about delivering the correct product in the expected condition and at the agreed time, place and price.

You avoid costly repair by safeguarding against variations and unnecessary changes in design and repair during production, which delay and increases the cost of production.

By a closely monitoring third party inspector’s presence – partly or constantly during manufacturing - the quality of the products are ensured so that errors are noticed and corrected as fast as possible during production.

Technical expertise from start to end

FORCE Technology offers technical expertise from start to end during production of welded steel structures and the following paintwork. We check the correctness of and inspect the welding and the performed paintwork.As the owner’s consultant and representative on the production site we ensure this throughout the project:

- Product quality

- Revelation of deviation from standard specifications as soon as possible in the production process

- Check whether standards, procedures and specifications are met

- Precise and timely reporting.

We audit suppliers before and maybe parallel to the course of production. This includes evaluation and revision of the sub-supplier’s production facilities as well as examination of procedures and specifications for production and production control. We also perform random NDT verification of steel and surface treatment so that you are sure that the quality of your product is OK.

We participate in meetings with your suppliers worldwide, where we offer current assistance in connection with treatment of possible deviations, if any, and corrective actions to the scope that you may need.

Tailor-made inspection programs

The individually tailored inspection programs, which particular focus on tracking and reporting, are adjusted in consultation with you and your wishes in relation to frequency and extent.

FORCE Technology has contributed with third party inspections within manufacturing of foundations, towers, platforms and general surface treatment and corrosion protection in the largest offshore projects. Through the last ten years our experienced and certified inspectors and engineers have thus gained knowhow from many projects around the world, with hands-on knowledge of manufacturing, building sites and various inspection methods.

Our experienced inspectors may for instance have a background as welding technicians (IWT) or welding specialists (IWS), and they have a wide knowledge of NDT (EN ISO 9712). In addition, inspection of coating and surface treatment is carried out by NS 476 (FROSIO) certified inspectors.

Contact us if you want assistance to quality assure production of your wind turbines.

Consultancy and inspection regarding steel manufacturing:

Welding and steel manufacturing consultancy is performed by inspectors with long and in-depth experience and training as welding technicians (IWT) or welding specialists (IWS) with a wide knowledge of NDT (EN ISO 9712) and could include the following:

- Consultancy on design of welded joints

- Quality control – including evaluation of plans for reception control and other quality assurance techniques throughout the process

- Materials – including examination of materials certificates, evaluation of methods for welding preparation etc.

- Presence during welding procedure tests (WPAR)

- Examination of welder’s certificates

- Control of storing and handling of fill materials

- Monitoring of production welding with control of equipment, adhesion, pre-heating, temperature, fill materials and that these are in accordance with welding procedures (WPS)

- Plans for correct welding sequence and welding certificates etc.

- Random NDT (non-destructive test) – including examination of reports, NDT procedures and specifications and NDT certificates for equipment and inspectors

- Instructions and procedures for special processes such as storing and handling of materials, preheating, cold and hot straightening

- Examination and final documentation.

Consultancy and inspection regarding coating and paintwork:

- Evaluation of need for corrosion protection

- Selection of methods for corrosion protection (galvanizing, thermal spraying, painting)

- Selection of paint types and documentation of specification for corrosion protection (coating specification/paint systems)

- Planning of work and documentation

- Tailor-made inspection procedures before, for under coats and after the final application of paint

- Consultancy on production, equipment and procedures

- Reporting and documentation

- Inspection before, under and after paintwork

- Control of pre-treatment: Cleaning, state, preparation of specific welds

- Paintwork: Thickness measurement, application, condition, craftsmanship

- Finish: Film (layer) thickness, adherence, colour

- Customer’s training of staff and training in painting and corrosion protection.

Services

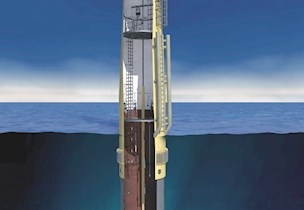

Monitoring of offshore wind turbine foundations

Our monitoring system for wind turbine foundations gives you early warning of possible flaws.

FROSIO-certified coating inspection

Make sure the surface finish on your steel structure is well done and remains intact and effective.

Measurements for structures and machinery

Measurements of loads, deformations, strains and vibrations, for general purpose and projects.