Welding consultancy

If you need to optimise and improve welding processes, equipment and materials or if you experience problems with preparing and performing welding tasks, FORCE Technology may assist you.

Determine your need for welding consultancy

Your need for welding consultancy may vary depending on your task, and you may be able to solve the tasks yourself by:

- Choosing and optimising welding processes

- Improving the welding productivity

- Choosing the right welding equipment

- Renting the best welding equipment

- Avoiding quality problems when welding

- Interpreting the standards and tender material.

If you need assistance we shall pay you a visit. Together we shall determine the extent and limits of the task and agree on the next steps as regards time schedule and reporting if so required.

Some tasks are not limited to welding only, and in such cases our welding technicians will draw on our knowledge within FORCE Technology’s other areas of expertise, e.g. use of sensors, non-destructive testing (NDT) or metallurgy.

Our welding technicians all hold many years’ experience from the welding industry and have diplomas from one of the international welding educations from EWF/IIW. This will ensure a technologically correct and practical solution.

Examples of welding consultancy:

Choice and optimisation of welding procedures:

FORCE Technology may assist at selection of welding procedures for new and ongoing tasks, as well as review of the processes as regards optimisation and increased productivity if requested.

It may be introduction of modified MAG-welding processes, by which you may increase the travel speed of welding and improve the welding quality as regards mechanical properties and welding defects.

Choice of welding equipment:

Optimisation of the welding process will often lead to automation/robotization of the welding equipment and we can assist in choosing the correct robot with the degrees of freedom necessary for your product.

Rental of welding equipment:

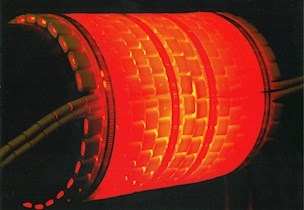

If your company is in need of welding equipment for a specific task, it is possible to rent it with us. This may be heat treatment equipment or a welding chamber for titanium welding.

Welding quality issues:

Finding the reason/reasons for welding defects requires thorough knowledge of process, materials and equipment and we will be able to assist you in this. The solution to the problem is often hidden elsewhere than expected. For instance, poor work piece connection may result in pores and so will moisture in the flux for submerged arc welding.

Interpretation of standards and tenders:

If your company has qualified welding procedures according to ISO 15614-1 for a number of years, and you wish to join the offshore market, we can assist you in identifying the additional requirements . If e.g. you need to meet Maersk Oil requirements, there will be other ranges of approval for material thickness, impact testing must be performed in 4 locations and the hardness requirements are more stringent.

Training and courses within welding consultancy

In connection with welding consultancy, there may be a need for courses and training. FORCE Technology provides a number of different courses and training. If your company requires other specific courses, please feel free to contact us so that we can tailor a course according to your wishes.

Contact us and discover how you get the best welding consultancy.

Services

Welding inspection

Inspection of the welding work is crucial in order to obtain the proper quality.

Strength analysis of welded structures

Strength analysis of welded structures can protect you from failure and accidents.

WPS - Welding Procedure Specification

Get help designing the required WPS so your welders can perform the welding work.