Welding inspection

Inspection of the welding work is crucial in order to obtain the proper quality. FORCE Technology holds many years’ experience in this field and is able to assist you.

Inspection during daily welding work and at major welding projects is so important that it should be performed by personnel that holds the necessary qualifications and is capable of handling the dialogue with welders and other personnel.

Welding technology inspection for owners and contractors

When your company is handling major projects with requirements for third party welding inspections, there will often be a need for welding inspectors and this is when your company can rely on FORCE Technology’s welding inspectors.

They all have certificates from one of the international welding educations from EWF/IIW and many years’ experience with inspection and are familiar with most applied welding standards and specifications.

Welding coordination within the company

It is necessary that welding companies are in contact with, and can make use of, a qualified welding coordinator in order to live up to the increasing demands of directives and customers. If your company does not have or need a full time employed welding coordinator, you can “rent” a welding coordinator with FORCE Technology.

The welding coordinator’s function will usually be laid down in a written agreement, which may be displayed during external audits of your company. Focus areas should be described in this agreement often refererring to ISO 14731 ”Welding coordination – Tasks and responsibilities”.

Such an agreement will also include conditions as to the presence of the welding coordinator. This could be once a week or for specific projects, according to agreement.

Examples of standards we have worked according to:

- MOTS Technical Standards for Maersk Oil

- DNV-OS-C401 Fabrication and Testing of Offshore Structures

- DNV-OS-F101 Submarine Pipeline Systems

- NORSOK standards

- API 6A, 16A, 16C, 16F, 16R, 17D

- ENERGINET.DK specifications for the natural gas transmission system

- DKF2002 Danske Kraftværkers Fællesbetingelser for svejsearbejde på rørsystemer

- PED European harmonised standards for pressure equipment.

Contact FORCE Technology and make an appointment so that we can sort out personnel with the required qualifications that will meet your requirements and time schedule.

Services

Welding consultancy – Improve weld quality

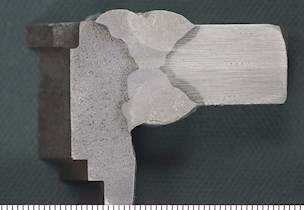

If you need to optimise and improve welding processes or find the reason for welding defects.

Status assessment and inspection

If failure is not acceptable, it is necessary to perform status assessments at suitable intervals.

Engineering critical assessment of welded structures

Is it safe to keep using a structure with flaws, without any risk of failure?