Electrochemical testing of corrosion

Get quantitative and precise corrosion data by using electrochemical testing

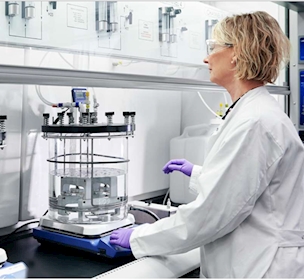

In our electrochemical testing facility, we identify the corrosion mechanism and measure the corrosion rate of metals using well-established principles. The obtained information is exact and quantitative, and it might be useful for defining safe-limits of stainless steel or evaluating the corrosivity of a product. The measurements can be made directly in your product, to ensure the most cost-optimal choice of material.

Standardised tests are provided, such as those used for testing stainless steel and corrosion resistant alloys (CRAs), e.g. ASTM G61 Cyclic Potentiodynamic Polarization and ASTM G150 Critical Pitting Temperature Testing. For corrosion testing of medical implant devices, ASTM F2129 or ISO 10993-15 are provided.

When there is no standard available, we define a customised test method based on the principles from the standards. Our qualified corrosion specialists also assist in defining accept criteria and making thorough interpretation that can be correlated with your service conditions. We have developed customised methods for tribo-corrosion (or corrosive wear), rapid detection of intermetallic phases in stainless steel, assessment of cathodic protection (CP) and hydrogen related damage etc.

We have a wide range of potentiostats providing all electrochemical techniques, i.e. DC, AC and EIS measurements. Our glassware and test setups are often custom-built to meet the requirements for doing special testing. We also perform electrochemical testing in autoclaves at temperatures up to 300 °C.

Hydrogen Induced Corrosion Testing

/Facility

Test materials for their susceptibility to hydrogen embrittlement and hydrogen induced failures.

Salt spray and climatic chamber testing

/Facility

Accelerated climate testing of materials, exposed to salt, moisture, heat and UV-radiation.

Large-scale corrosion testing

/Facility

Large components are tested at extreme conditions

Pitting, intergranular and immersion corrosion testing

/Facility

Immersion testing according to standards or customized protocols.

HPHT testing in realistic environments

/Facility

Test facilities for testing of metals, coatings, polymers, composites and assemblies/ components.