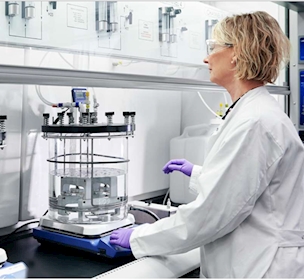

Large-scale corrosion testing

Large components are tested under extreme conditions

Our facility enables testing of large components under extreme conditions, offering unique insights into performance and system integrity.

The test setup includes a specialized safety chamber designed to handle hazardous chemicals and gases under high pressure and temperature. This advanced equipment supports a range of tests, including performance evaluations, system integrity assessments, and burst testing.

In addition to industry-standard tests conducted in autoclaves, our large-scale chamber allows for failure analysis and validation testing. By identifying the root causes of failures, companies can implement measures to prevent recurrence.

The test chamber, embedded within a larger safety container, facilitates full-scale evaluations such as:

- Testing pipeline segments filled with corrosive solutions

- Assessing sensors in hot corrosive gases

- Burst testing of new fitting designs

This large-scale capability ensures comprehensive testing for a wide range of components.

Hydrogen Induced Corrosion Testing

/Facility

Test materials for their susceptibility to hydrogen embrittlement and hydrogen induced failures.

Salt spray and climatic chamber testing

/Facility

Accelerated climate testing of materials, exposed to salt, moisture, heat and UV-radiation.

Electrochemical testing

/Facility

Obtain quantitative and precise corrosion data by using electrochemical testing.

Pitting, intergranular and immersion corrosion testing

/Facility

Immersion testing according to standards or customized protocols.

HPHT testing in realistic environments

/Facility

Test facilities for testing of metals, coatings, polymers, composites and assemblies/ components.