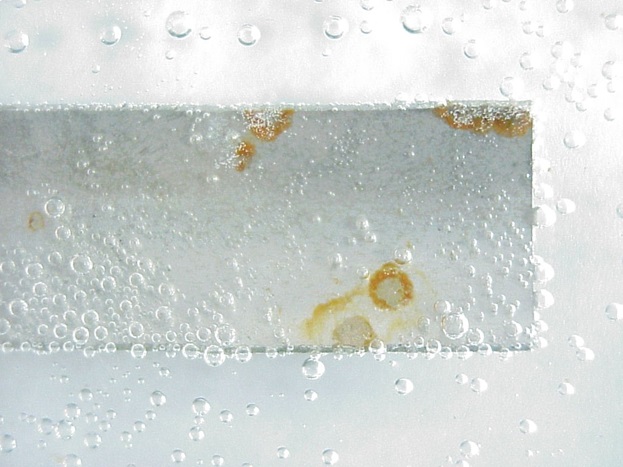

Pitting, crevice, intergranular and immersion corrosion testing

Immersion testing according to standards or customized protocols.

At our corrosion testing facility, we specialize in pitting, crevice, intergranular, and immersion corrosion testing using well-recognized standard methods and customized protocols.

Immersion testing: standards and tailored protocols

Immersion testing typically involves weighing, controlled exposure, and a detailed evaluation of metal coupons. While the process may appear straightforward, the expertise of our experienced corrosion engineers is essential for proper test planning, execution, and interpretation.

Stainless steel testing standards

We frequently assess stainless steel alloys using industry standards, including:

- Intergranular corrosion testing:

- ASTM A262

- ASTM G28

- ISO 3651 (Strauss and Huey tests)

- Stress corrosion cracking (SCC):

- ASTM G36 (boiling magnesium chloride solution)

- Pitting and crevice corrosion:

- ASTM G48, ASTM A1084, ASTM A923

We also adhere to ISO or EN equivalent standards and business-specific protocols such as NORSOK, DNVGL, and SAIPEM to meet diverse industry requirements.

Immersion testing for other applications

Our capabilities extend to additional immersion testing, such as:

- ASTM G31: General corrosion in controlled environments.

- UN/DOT Section 37: Qualification of metals for hazardous chemical transport.

Custom test protocol development

When standard methods don’t meet your requirements, our team works closely with you to develop customized test protocols tailored to your application. We have extensive experience designing tests for challenges like:

- CUI (corrosion under insulation): Simulating real-world environmental conditions.

- Corrosion inhibitor qualification: Evaluating chemical performance and effectiveness.

- Cleaning procedures for corrosion coupons: Ensuring accurate preparation for reliable results.

Why choose us?

- Expertise you can trust: Decades of experience in corrosion testing and interpretation.

- Comprehensive services: From standardized tests to fully tailored protocols.

- Industry recognition: Proven adherence to global and business-specific standards.

We are committed to providing actionable insights and helping you ensure the durability and reliability of your materials in even the most challenging environments.

Related facilities

Hydrogen Induced Corrosion Testing

/Facility

Test materials for their susceptibility to hydrogen embrittlement and hydrogen induced failures.

Salt spray and climatic chamber testing

/Facility

Accelerated climate testing of materials, exposed to salt, moisture, heat and UV-radiation.

Electrochemical testing

/Facility

Obtain quantitative and precise corrosion data by using electrochemical testing.

Large-scale corrosion testing

/Facility

Large components are tested at extreme conditions

HPHT testing in realistic environments

/Facility

Test facilities for testing of metals, coatings, polymers, composites and assemblies/ components.