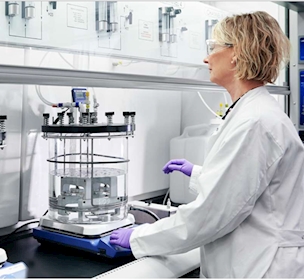

Salt spray and climatic chamber testing

Accelerated climate testing of materials, exposed to salt, moisture, heat and UV-radiation.

FORCE Technology has many years of experience with accelerated climate testing of materials with or without surface treatments/coatings and paints. FORCE Technology has cabinets for salt spray testing, humidity testing and UV-radiation.

We can perform salt spray (salt fog) tests under variety of corrosive environments. For a typical salt spray test, a highly corrosive atmosphere is created by heating the cabinet to 35° C and exposing test elements to 5% NaCl. Testing is carried out in accordance with international ISO, EN and ASTM standards, for example DS/EN ISO 9227.

Humidity chamber testing is carried out by applying constant or interrupted moisture, with or without corrosive gases. Testing is carried out in accordance with international ISO, EN and ASTM standards such as DS/EN ISO 3231:1998.

FORCE Technology also offers accelerated aging and UV weathering testing.

Hydrogen Induced Corrosion Testing

/Facility

Test materials for their susceptibility to hydrogen embrittlement and hydrogen induced failures.

Electrochemical testing

/Facility

Obtain quantitative and precise corrosion data by using electrochemical testing.

Large-scale corrosion testing

/Facility

Large components are tested at extreme conditions

Pitting, intergranular and immersion corrosion testing

/Facility

Immersion testing according to standards or customized protocols.

HPHT testing in realistic environments

/Facility

Test facilities for testing of metals, coatings, polymers, composites and assemblies/ components.