Competitive and reliable material selections for future energy supply (ENFOS)

Competitive and reliable material selections will improve the competitiveness of Danish small- and medium-sized businesses and contribute to a green transition.

Purpose

The project will support the development of green technology.The transition from fossil energy to green energy introduces new challenges for systems, materials, and equipment. Systems are exposed to increasingly aggressive chemical environments at high pressures and temperatures. Increased process optimisation and a focus on competitiveness also contribute to the increased pressure on these new technologies.

Today, FORCE Technology offers knowledge and facilities that help Danish companies choose and document materials for the energy sector. This project will expand this platform of services, based on testing facilities for harsh environments.

Consultancy and testing facilities will help Danish companies qualify products and designs for facilities for green energy technology. This project will thus support the development of green technology by improving the competitiveness of Danish small- and medium-sized businesses, and by contributing to a larger flow of new technology for the green transition.

Target group

The target groups are:

- companies developing new technology for energy facilities

- manufacturers of new energy technology equipment, both current and future

- energy facility operators and owners.

Partners

Several companies will be involved in demonstration activities. At the moment, these include Bigadan A/S, Elysium Nordic Aps, WattsUp Power A/S and Aalborg CSP A/S.

In addition, we have established an advisory board, which we use for professional sparring. The advisory board ensures that the activity is constantly focused on technology development and innovation efforts, adapted to the needs of the industry, while at the same time establishing important links with and between companies.

Previous project periods

This project builds on the "Materials in Harsh Environments" project (2017–2019), and is related to the GEOTHERM, EEEHy, and CeJacket innovation fund projects.

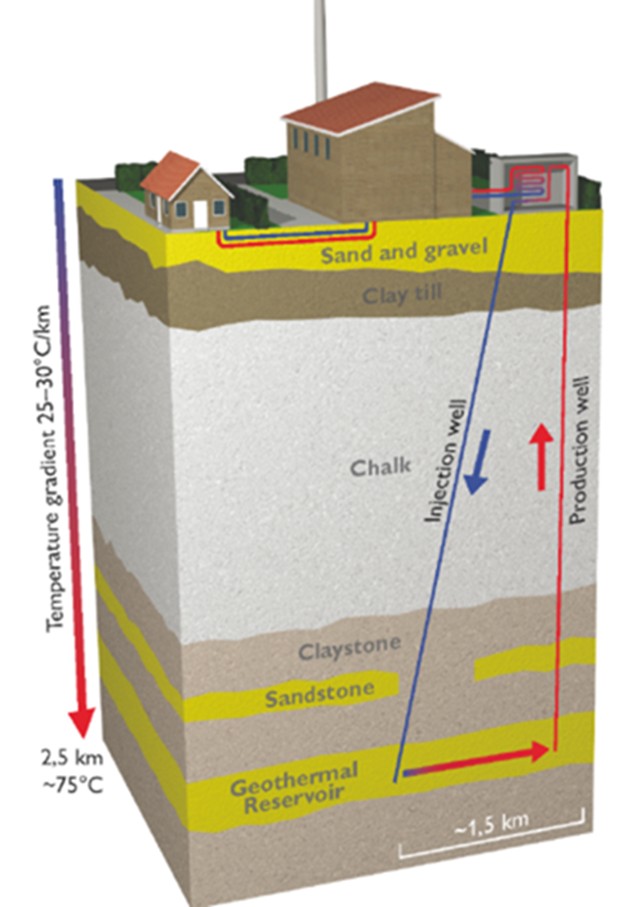

The GEOTHERM project shows the way for the utilization of geothermal energy in Denmark

In a project led by GEUS, FORCE Technology has contributed with material knowledge and corrosion testing. What materials can be used when the geothermal water for heating is three to four times as salty as seawater? In the project, several best practice reports and final reports have been prepared, which shed light on this. Read more about the project here.

Technological solutions for the energy supply of the future

The green transition requires new technological solutions. The Danish Technological Institute and FORCE Technology held a webinar on 20 November 2020. The results of two projects were presented. Examples were given on how SMEs and GTS (RTOs) deal with new material challenges and apply modelling tools as a basis for decision-making in the green transition. The plans for upcoming projects in GTS were reviewed and discussed.

Hydrogen permeability in GRP, PTFE and metals

Biogasclean is specialized in biological removal of sulphur from biogas without the use of chemicals. In this demonstration project Biogasclean along with their partners (Nature Energy, SDU and DTU) in an external project, wanted to examine if there could be material challenges by adding hydrogen to increase the yield of methane and decrease the CO2 levels.

Due to the small size of the hydrogen atom there is a risk of diffusion into other materials with potential harmful effects. A literature study has been carried out on the possible impact of hydrogen on materials for a pilot plant, more specifically glass fibers and resin types most frequently used, as well as metallic components.

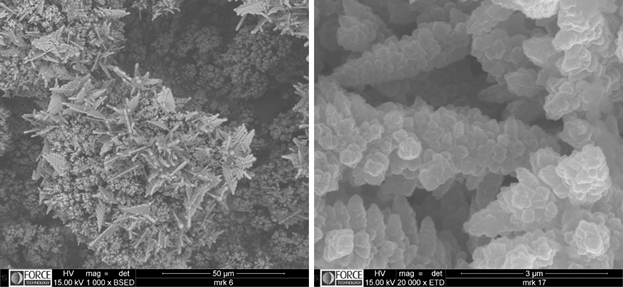

Characterization of catalysts for electromagnetic and high-pressure electrolysis

The work entails a collaboration between HYMETH and FORCE Technology, with the focus on characterizing and qualifying new technologies for green energy transition. Here, FORCE Technology further develops and improves characterisation and qualification methods for high surface area microstructures. Proper characterisation method helps HYMETH to optimize highly efficient catalyst for electromagnetic and High-Pressure Electrolysers.

The SEM images show state-of-the-art patented noble metal free electrocatalyst material produced by HYMETH.

Longer service life of transport systems for biomass

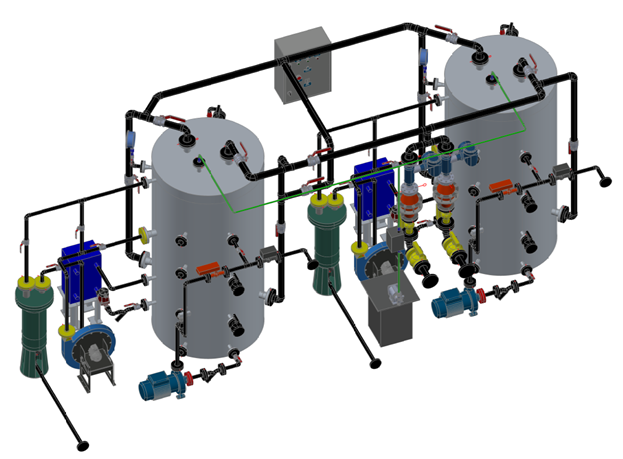

Bigadan A/S v. Kalundborg Bioenergi A/S, together with FORCE Technology, has looked at the service life of transport systems for biomass in biogas production. The use of new types of residual products from industry often results in increased wear and faster corrosion of the metal parts than traditional biomass. Measurements have been made in a newly developed test set-up which can recreate the problem, so that new material solutions can be tested to obtain longer service life.

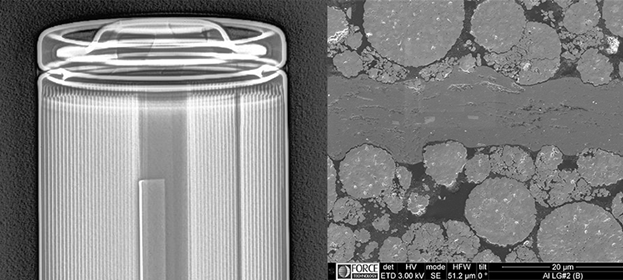

Failure analysis of Lithium ion batteries

Batteries can be used to propel cars, ferries and trains, but are also used to a greater extent to store electricity from wind turbines, solar energy, etc. As the use of batteries increases sharply, the requirements for durability and robustness also increase. To assess such parameters, batteries are exposed to simulated conditions in the laboratory, so-called accelerated lifetime tests. In this demonstration project, accelerated lifetime tests of a variety of lithium ion batteries were performed. The worn out batteries were then investigated, using both nondestructive and destructive techniques. The internal parts of the batteries are degraded differently, depending on the external loads, and through a failure analysis it is possible to assess the effects that a battery has been exposed to. Read our article here.

Material selection for water/steam boilers

Aalborg CSP A/S is among global leading steam generator suppliers, within the concentrated solar power (CSP) segment. FORCE Technology has evaluated the corrosion challenges of boiler steels, related to the boiler water temperature and quality. FORCE Technology has written a pre study, where factors influencing the corrosion mechanism and the durability of steel alloys used in water/steam boilers are addressed. The pre study also includes material recommendations for a specific relevant boiler application.

Material selection for pyrolysis

Elysium Nordic Aps builds one of the world's largest pyrolysis plants for the recovery of end-of-life car tires. FORCE Technology participates in the dialogue about material selection for the plant's unique pyrolysis reactor, where carbon black is recovered from the tires so that it can be included in new rubber-based products. High temperature and special gas mixtures must be considered when selecting the reactor material.

Special test of flywheels for energy storage

WattsUp Power A/S supplies advanced flywheel systems for energy storage. FORCE Technology has measured the mechanical strength of the composite in a new flywheel design. The special assignment required the development of a special fixture and a new test protocol that addresses the difficulties of testing fiber-reinforced composites with complex geometry.

Seminar - November 22, 2019

Under the title Green transition requires innovative material solutions, we held a seminar with 27 participants from Danish companies and organizations.

The participants gained insight into the project's demonstration cases within biogas, concentrated solar energy, pyrolysis, batteries, geothermal energy and offshore wind. It was illustrated with practical cases.

A new test laboratory was presented, including autoclaves, a double-proof test chamber and specialized facilities for handling difficult gases.

The advisory board, which includes 12 Danish companies, was given the opportunity to comment on the project's progress and course.

Articles and presentations

- English: Customized testing of bolted connections for large subsea wind structures

- Danish: Temadag grøn omstilling kræver innovative materialelæsninger

- Danish: Demonstrationsopgaver biogas solenergi og pyrolyse

- Danish: Korrosion og scaling i geotermisk vand

- Danish: Skadesundersøgelse af lithium ion batterier

- English: Specialtest af boltede samlinger til store havmøllefundamenter

Technological solutions for the energy supply of the future

The green transition requires new technological solutions. The Danish Technological Institute and FORCE Technology held a webinar on 20 November 2020. The results of two projects were presented. Examples were given on how SMEs and GTS (RTOs) deal with new material challenges and apply modelling tools as a basis for decision-making in the green transition. The plans for upcoming projects in GTS were reviewed and discussed.

Hydrogen permeability in GRP, PTFE and metals

Biogasclean is specialized in biological removal of sulphur from biogas without the use of chemicals. In this demonstration project Biogasclean along with their partners (Nature Energy, SDU and DTU) in an external project, wanted to examine if there could be material challenges by adding hydrogen to increase the yield of methane and decrease the CO2 levels.

Due to the small size of the hydrogen atom there is a risk of diffusion into other materials with potential harmful effects. A literature study has been carried out on the possible impact of hydrogen on materials for a pilot plant, more specifically glass fibers and resin types most frequently used, as well as metallic components.