The wind energy value chain:

Step 3: Installation

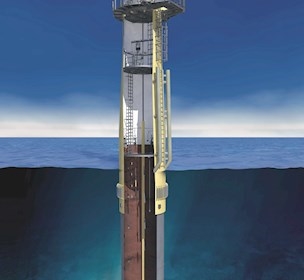

From design to decommissioning, every step in the wind energy value chain presents unique challenges. During the critical installation phase, we offer solutions to streamline processes, minimize risks, and ensure project success for both onshore and offshore wind farms.

How can mobilisation and installation be streamlined for onshore and offshore wind farms?

Onshore installations face challenges like road access to remote wind farm sites. Offshore projects, reliant on vessels and cranes, are often delayed by weather conditions. These logistical hurdles can slow progress and increase costs if not addressed early.

Based on 30 years of experience with on and offshore design, we see that focusing on these logistic elements early on allows for a smoother installation phase and better project completion.

That is why we opt for a modular-based design which gives flexibility and low cost.

Use simulations to prepare the installation and crew

Our virtual test center lets you assess and refine installation methods, vessel designs, and personnel transfer concepts under real-world environmental conditions. This ensures safety, efficiency, and readiness for any scenario. Our cloud-based simulator services are suited for feasibility and engineering studies but can also help train your crew anytime, anywhere.

With our cloud-based maritime training simulator, you always have the most recent content and training methods available. The focus is on flexibility, allowing you to receive high-quality training remotely with equipment suited to your team's exact needs. This creates a realistic simulation tailored to any situation or processes you wish to simulate. Depending on your needs, the cloud concept comes in different versions, with or without augmented reality.

Monitoring solutions provide early warning of possible flaws

With our structural monitoring solution, you can detect potential defects early, avoid costly repairs, and maximize the lifespan of your wind turbine investments.

If you, as a wind turbine owner, investor or operations manager, want to validate the health of your investment, you should monitor the foundation and the rest of the wind turbine for loads, vibration, fatigue stress, temperature and corrosion. Doing this ensures that the turbine maintains its functionality, and you avoid tremendous costs regarding repair and retrofit.

Prevent future faults with condition monitoring systems

Early warning of flaws enables you to act and correct them in time, avoiding possible severe weaknesses in the structure. Detecting the cause of defects helps prevent future faults and avoid flaws in similar wind turbine foundations. You can use the data for corrective actions and optimising sub-components and design.

Structural health monitoring systems are all customer-specific, and we design and optimise a condition monitoring solution adjusted to your needs, information needs and budget.

We can design, supply and install unique condition monitoring systems for wind turbine foundations and assist with the subsequent data processing, evaluation, assessment and consultancy and field services to customers who do not have internal specialists on staff.

Fast, flexible, agile and ready to adapt

Our interdisciplinary team delivers ultimate quality. With more than 1,000 employees across 30 offices in 6 countries and a dedicated local partner network, we are a market leader in specialist consultancy, testing, inspection, and training.

60+ years of experience

Many companies offer integrity management, experimental tests and simulations, non-destructive testing, failure analysis, calculations, design verifications or condition monitoring. What sets us apart is our ability to offer all necessary services under one roof, from testing to advanced strategic advice.

We are accredited by DANAK, the Danish Accreditation body. This means that we are continuously assessed against internationally recognised standards to demonstrate competence, impartiality and performance capability. Our accreditation ensures that your products meet all applicable regulatory standards.

Design, test and validation

How can you know if your wind structure or part can withstand the environment?

Production

How can you ensure that your products work, last, are safe and compliant?

Mobilisation and installation

How can mobilisation and installation be streamlined for onshore and offshore wind farms?

Operation and maintenance

How do you reach long-term success with maintenance and inspection strategies?

End-of-life

How do you extend a wind turbine's lifespan and manage its end-of-life sustainably?

Related services

VR remote maritime simulator for training

/Service

Monitoring of offshore wind turbine foundations

/Service

Our monitoring system for wind turbine foundations gives you early warning of possible flaws.