The wind energy value chain:

Step 1: Design, test and validation

The wind value chain starts with design and testing before production, installation, operations, and decommissioning. Here are some issues we can help you with during the design phase.

How can you know if your wind structure or part can withstand the environment?

The design of a wind project is the very first step in the wind energy value chain. It starts with a lifetime assessment considering the extremely harsh conditions in which the wind turbine system or part must operate.

A lifetime assessment is crucial to the operation of most steel constructions, and it helps you to plan maintenance and repair, avoid failure and minimise revenue loss.

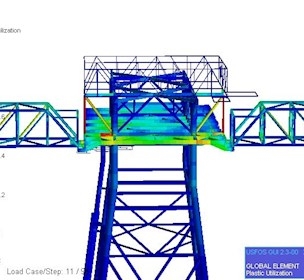

You need to consider both ultimate and fatigue loading, understand wind/wave characteristics and their interactions and know how to precisely predict collective influence on these complex, dynamic systems in the lifetime assessment. Our climatic test chamber can test large components, structures and functional systems under realistic atmospheric sea conditions. Temperature control, humidity control and salt spray can be individually controlled or programmed as combined effects to simulate the harsh offshore atmosphere as realistically as possible.

Our extreme and special tests provide you with documentation demonstrating your product's resistance to the environment and can be a part of determining its life expectancy.

Make use of our decades of experience in designing, testing and validating wind projects to:

60+ years of experience

Many companies offer integrity management, experimental tests and simulations, non-destructive testing, failure analysis, calculations, design verifications or condition monitoring. What sets us apart is our ability to offer all necessary services under one roof, from testing to advanced strategic advice.

We are accredited by DANAK, the Danish Accreditation body. This means that we are continuously assessed against internationally recognised standards to demonstrate competence, impartiality and performance capability. Our accreditation ensures that your products meet all applicable regulatory standards.

Design, test and validation

How can you know if your wind structure or part can withstand the environment?

Production

How can you ensure that your products work, last, are safe and compliant?

Mobilisation and installation

How can mobilisation and installation be streamlined for onshore and offshore wind farms?

Operation and maintenance

How do you reach long-term success with maintenance and inspection strategies?

End-of-life

How do you extend a wind turbine's lifespan and manage its end-of-life sustainably?

Related

EMC, reliability and safety

/Service

Welding consultancy – Improve weld quality

/Service

If you need to optimise and improve welding processes or find the reason for welding defects.

Lifetime assessment of wind turbine structures

/Service

Lifetime assessment helps you plan and avoid breakdowns in wind turbine towers and foundations.

Advanced structural engineering with CFD

/Service

We offer computational fluid dynamic analysis within various areas, performed in flow conditions.

Type testing of marine products

/Service

Advisory services and accredited type testing of marine products.

Extreme test for harsh environments

/Service

Our extreme and special test provides evidence of the product's resistance to harsh environments.

Cathodic protection optimisation

/Service

Cathodic protection (CP) services, incl. design, modelling, survey and retrofit life extension.

Materials selection and corrosion protection

/Service

The correct materials and optimal corrosion protection gives your product a longer service life.

Test and analysis of plastics and composites

/Service

Ensure optimal material selection and design when working with polymers and composites.

Mechanical tests of large structures

/Facility

Full-size structures can be exposed to static and dynamic multi-axial loads or fatigue testing.