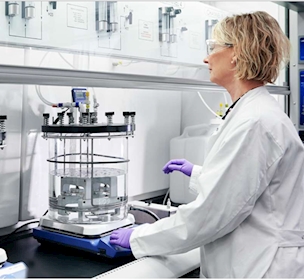

High pressure high temperature (HPHT) test in realistic environments

HPHT (autoclave) test facilities for testing of metals, coatings, polymers, composites and assemblies/ components.

In our high pressure high temperature (HPHT) test facility, we perform high pressure high temperature testing (i.e. autoclave testing) of metals, coatings, polymers, composites and assemblies/components in aggressive environments.

We have comprehensive experience in designing fit for purpose qualification test-methods, and accelerated durability testing, for various applications. With our state-of-the art test equipment we offer tests in e.g. sour-and sweet environments, acidic- and alkaline environments, with flow of gas or liquid, high gas loading, under bending or tension, with rotation, with chemical/inhibitor dosing, mixed gas environment and etc.

The provided tests include:

- Electrochemical testing at HPHT e.g. corrosion speed (mm/year), electrocatalytic behaviour/performance

- Hydrogen induced cracking (HIC)

- Hydrogen Induced Stress Cracking (HISC)

- Stress Corrosion Cracking (SCC)

- Sulphide stress cracking (SSC)

- Autoclave test system with flow

- Customised testing

- Standardised testing according to e.g. EN, ASTM and NACE

We hold experience in supplying test solutions for:

- Power-to-Gas industries, e.g. components for water electrolysis systems

- Bio-to-Oil industries, e.g. pyrolysis and hydrothermal liquefaction

- Geothermal industries

- Biogas- and waste handling

- Pharmaceutical and food industry

- Chemical and petrochemical industries

- Cleantech industry

- Pyrolysis, combustion, and motors/engines

- Paper and pulp industry

- Oil and gas industry

- Carbon Capture and Storage (CCS)

Test possibilities in the HPHT laboratory

The HPHT laboratory holds specialised equipment and facilities, to test your candidate materials:

- Pressure 0-350 bar

- Temperatures (25-350 °C)

- Flow simulation or other movement

- Possibility for dosing of chemicals and gas mixtures during testing

- Electrochemistry directly in the autoclave (HPHT reference electrode).

Full scale equipment for large components

The full scale test laboratory is used to test large components.

The facility comprises a safety container with an inserted test container. The equipment facilitates performance test of components or system integrity tests for e.g. damage and failure or validation testing to ensure compliance with your requirements.

HSE requirements are met

We meet the strictest safety requirements, for personal protection as well as environmentally – with triple safety barriers for pressurised tests, removal of hazardous gasses in scrubber units and collection of fluids for neutralisation tanks.

Related services

Screening metallic materials for hydrogen embrittlement

/Service

Corrosion testing of materials and components for CCS

/Service

Related facilities

Hydrogen & CCUS HPHT testing facility

/Facility

Hydrogen Induced Corrosion Testing

/Facility

Test materials for their susceptibility to hydrogen embrittlement and hydrogen induced failures.

Electrochemical testing

/Facility

Obtain quantitative and precise corrosion data by using electrochemical testing.

Large-scale corrosion testing

/Facility

Large components are tested at extreme conditions

Pitting, intergranular and immersion corrosion testing

/Facility

Immersion testing according to standards or customized protocols.