Non-destructive testing (NDT)

Non-destructive testing is an essential element in maintaining safe and continuous operations in any sector. We can aid with both standard and advanced NDT tasks.

Order inspection and/or NDT here

Order NDT or inspection

/Service

Condition montitoring or monitoring of manufacturing process with NDT

Condition monitoring with NDT

/Service

Non-destructive testing of components, constructions, and systems in operation onshore and offshore.

Monitoring manufacturing process with NDT

/Service

With NDT in the manufacturing process you can document compliance with standards and requirements.

Automated or manual inspection of manufacturing process or systems in operation

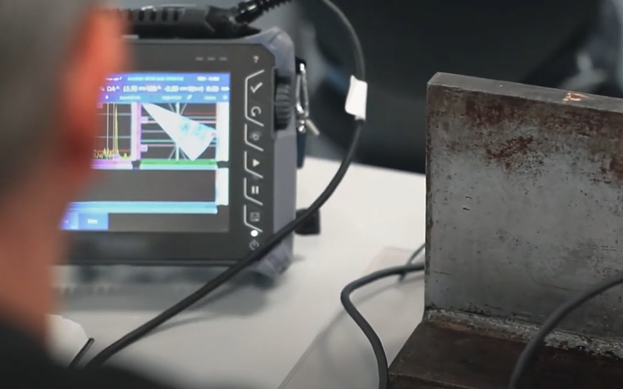

Ultrasound inspection for systems in operation

/Service

Automated ultrasound inspection can be used to analyse the state of components and systems in operation.

Cloud-based, automated ultrasound inspection

/Service

Automated, cloud-based ultrasound inspection reduces inspection time and secures data.

X-ray and ultrasonic inspection in production lines

/Service

Optimising manufacturing process control and product quality with X-ray and ultrasonic inspection.

Advanced automated NDT System for precise inspections (P-scan)

Blade inspection from production to in-service use

/Service

Ultrasonic blade inspection solutions for wind turbines in manufacturing and in-service use.

Advanced automated NDT System for precise inspections

/Service

P-Scan detects and evaluates defects in welds, pipelines, and vessels, ensuring precision and safety

Additional NDT services

X-ray measuring systems

/Service

Our X-ray measuring systems are build to optimise your production, reduce consumption and much more.

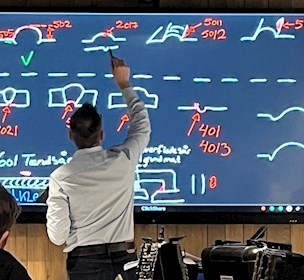

Consultancy and verification

/Service

We offer consultancy and key personnel within QA, QC, NDT, certification of personnel and more.

Cutting-edge care for underwater assets

/Service

Intelligent subsea inspection solutions to inspect structures and pipelines of various geometries.

Digital X-ray inspection

/Service

Digital X-ray inspection of everything from laser welds and microchips to paintings.

Ammonia tank inspection

/Service

In-service inspection of ammonia tanks provides a significant economical benefit.

Radiation consulting services

/Service

Consultancy within industrial application of ionising radiation, incl. radioactive isotopes.

Related content

Your partner for NDT products

We offer a broad range of top-quality NDT equipment and accessories designed to support your NDT inspections.

See the full range and contact us for all your NDT product needs here.

You may also be interested in:

Visual inspection course boosts supervision at Norsyn

/Case

Continued training strengthened Norsyn's staff expertise and the quality of weld inspections.

X-ray inspection ensures flawless AM parts

/Case

Discover how Orbex uses X-ray tomography for flawless additive manufacturing of parts for rockets.

Revolutionizing subsea inspection of CP systems

/Article

FiGS® offers non-contact assessments, boosting maintenance efficiency and extending CP systems' lifespan.

P-scan 5 update enables fast reliable corrosion mapping

/Article

FORCE Technology has enhanced the P-scan 5 system with new software for the existing package.

Case Study: Wind turbines ready for operation

/Case

Discover how comprehensive testing of offshore wind turbines ensures operational safety.

Inspection of Øresteds hot water storage for k-weld

/Case

Phased array ultrasonic inspection (PAUT) of storage tank on the CHP Skærbæk Power Station.