Materials - consultancy, test, analysis, and control

In-depth knowledge of the contents and composition of your materials ensures qualified decision processes - during design, operation, failure or damage.

Test, analysis, and control of materials

- Identification of foreign bodies and contaminants

- Screening metallic materials for hydrogen embrittlement

- Consultancy on Danish and European chemical legislation

- Corrosion testing of materials and components for CCS

- Materials examination and consultancy on constructions

- Testing of syringes, needles and safety boxes

- Standardised tests and special procedures - materials

- Analysis of steel and other metals

Mechanical testing

Food, pharma, and consumer products

Our facilities

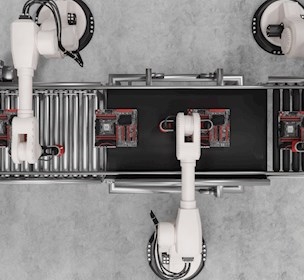

Hydrogen & CCUS HPHT testing facility

/Facility

Test and validate components in hydrogen and CCUS gas environments under realistic HPHT conditions.

Centre for Hygienic Design

/Facility

Hygienic design and product safety for the food, biotechnology, and pharmaceutical industries.

Surface characterisation laboratory

/Facility

Advanced equipment for surface characterization and analysis - including 3D, microscopy and X-ray.

Chemical analysis laboratory

/Facility

In our chemical analysis laboratory, we perform characterisation of all types of substances.

Related content

Webinar on Hydrogen infrastructure and power-to-x

/Event

Hydrogen and Power-to-X: Materials, testing, human factors and safety for the green transition

Secure quality with inde-pendent building assessments

/Industry

Independent building advisor for quality, safety and compliance.

Why recycled plastic ground protection mats crack

/Case

Material analysis of recycled plastic at Letbek identified the optimal PP–PE mix ratio.

Methanol handling course improves safety

/Case

Technicians at Nordhavn Power Solutions A/S now know how to manage safety and methanol-related risks.

Can natural gas infra-structure handle hydrogen?

/Article

Exploring the hydrogen value chain in an innovation project supported by the Just Transition Fund.

Denmark as a CO₂ Hub – Scaling and market development

/Project

The initiative advances knowledge in materials, emissions and metrology to strengthen CCUS efforts.

Power-to-X: From green vision to global business

/Project

This initiative strengthens infrastructure, scaling and capacity through expertise and efficiency.

Resilient and competitive production

/Project

How do we boost productivity and cut waste? Knowledge fosters a resilient and sustainable industry.

Robust energy system for green transition

/Project

Energy storage and conversion technologies improve through testing, demonstration, and development.